Product Description

Product Description

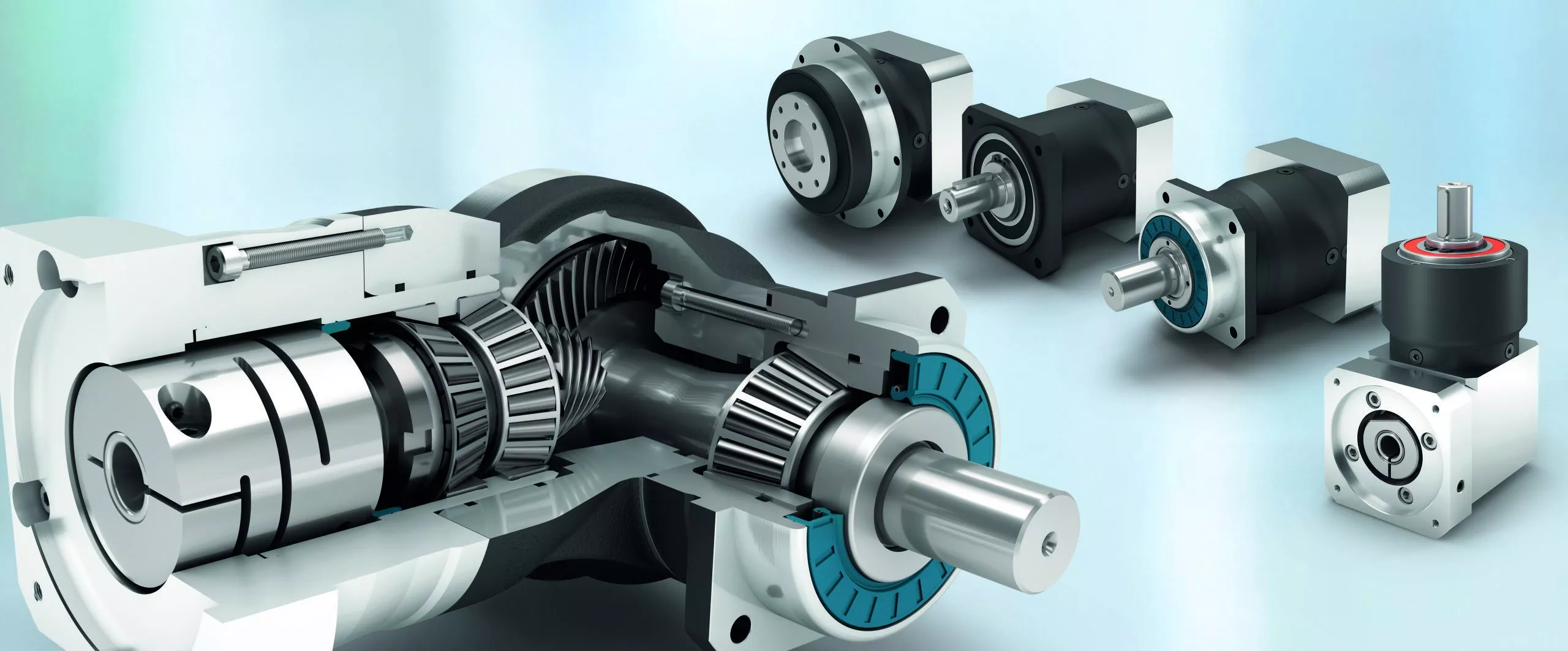

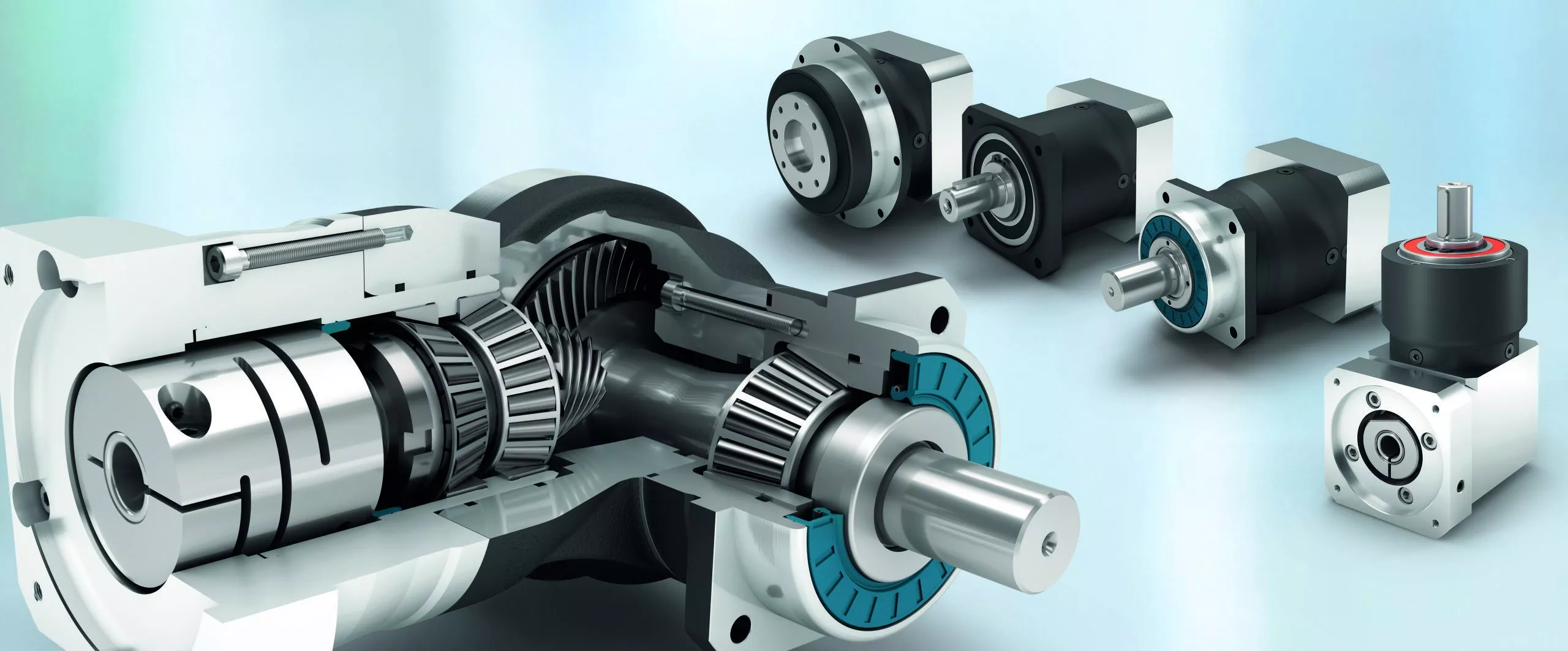

The NBR115 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The NBR115 series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NBA115 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

ultra-precision

Small size

Detailed Photos

Product Parameters

| Segment number | Double segment | ||||||||||||||||

| Ratio | i | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 140 | 160 | 180 | 200 |

| Rated output torque | Nm | 300 | 290 | 280 | 240 | 210 | 210 | 290 | 280 | 240 | 210 | 210 | 290 | 280 | 240 | 210 | 210 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||||||||||

| Rated input speed | Rpm | 4000 | |||||||||||||||

| Max input speed | Rpm | 8000 | |||||||||||||||

| Ultraprecise backlash | arcmin | ≤4 | |||||||||||||||

| Precision backlash | arcmin | ≤7 | |||||||||||||||

| Standard backlash | arcmin | ≤9 | |||||||||||||||

| Torsional rigidity | Nm/arcmin | 25 | |||||||||||||||

| Max.bending moment | Nm | 6700 | |||||||||||||||

| Max.axial force | N | 3350 | |||||||||||||||

| Service life | hr | 20000(10000 under continuous operation) | |||||||||||||||

| Efficiency | % | ≥92% | |||||||||||||||

| Weight | kg | 14.2 | |||||||||||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||||||||||

| Lubrication | Synthetic grease | ||||||||||||||||

| Protection class | IP64 | ||||||||||||||||

| Mounting Position | All directions | ||||||||||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤68 | |||||||||||||||

| Rotary inertia | Kg·cm² | 2.25 | 1.87 | ||||||||||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Handling Sudden Changes in Direction and Speed with Servo Gearboxes

Servo gearboxes are designed to handle sudden changes in direction and speed effectively, ensuring precise motion control even during dynamic operations. They employ several mechanisms to address these challenges:

1. Acceleration and Deceleration Profiles: Servo systems can be programmed with specific acceleration and deceleration profiles. This means that when a sudden change in speed or direction is commanded, the system can ramp up or down the speed smoothly, reducing the impact of sudden changes on the mechanical components.

2. Closed-Loop Control: Servo systems operate in a closed-loop configuration, where feedback sensors continuously monitor the actual position and speed of the system. When a sudden change is commanded, the controller can make real-time adjustments to ensure the system reaches the desired position accurately and smoothly.

3. Torque Control: Servo gearboxes are designed to provide high torque output even at low speeds. This is crucial for handling sudden changes in direction and speed, as the gearbox can deliver the required torque to quickly accelerate or decelerate the load.

4. Dynamic Response: Servo systems have fast dynamic response capabilities, which means they can quickly adapt to changes in input commands. This responsiveness allows the system to handle sudden changes in direction and speed without sacrificing accuracy or stability.

5. Electronic Damping: Some advanced servo systems incorporate electronic damping mechanisms that can be adjusted based on the application’s requirements. This feature helps dampen vibrations and oscillations that may occur during sudden changes in motion.

6. Overcurrent and Overvoltage Protection: Servo systems are equipped with protection mechanisms that detect excessive currents or voltages. If a sudden change in direction or speed causes abnormal loads or voltages, the system can take corrective actions to prevent damage.

Overall, servo gearboxes excel in handling sudden changes in direction and speed by leveraging their closed-loop control, high torque output, and fast dynamic response capabilities. These features allow them to provide accurate and reliable motion control in dynamic and rapidly changing operating conditions.

Customization of Servo Gearboxes for Specific Industrial Needs

Servo gearboxes can indeed be customized to meet specific industrial requirements. Manufacturers offer customization options to ensure that the servo gearboxes are optimized for the intended applications:

1. Gear Ratio Selection: Depending on the desired speed and torque output, manufacturers can provide various gear ratios to achieve the required motion characteristics.

2. Torque and Speed Ratings: Servo gearboxes can be tailored to handle different torque and speed demands, ensuring that they can efficiently operate within the specified parameters of the application.

3. Mounting Configurations: Manufacturers offer various mounting options, such as flange mounts or shaft mounts, to suit the mechanical layout of the machinery.

4. Output Shaft Configuration: Custom output shaft configurations, such as different diameters or keyway options, can be provided based on the integration requirements.

5. Environmental Considerations: For applications with specific environmental conditions, such as high humidity or extreme temperatures, servo gearboxes can be designed with protective features or special coatings.

6. Lubrication and Sealing: Custom lubrication options and sealing mechanisms can be incorporated to ensure optimal performance and longevity in the given environment.

7. Feedback Devices: Some applications may require specific feedback devices, such as encoders or resolvers, for precise motion control. Manufacturers can integrate these devices into the gearbox design.

8. Noise Reduction: Customized designs can include features that reduce noise and vibration, which is crucial in noise-sensitive applications.

9. Compact Designs: Manufacturers can work on compact designs to accommodate space constraints in the machinery.

10. Integration with Motors: Customized servo gearboxes can be designed to seamlessly integrate with specific types of motors, ensuring efficient power transmission.

By offering customization options, manufacturers enable industries to obtain servo gearboxes that perfectly align with their unique industrial needs, ultimately enhancing performance, precision, and overall system efficiency.

Benefits of Using a Servo Gearbox for Precise Motion Control

Servo gearboxes offer several advantages when it comes to achieving precise motion control in various applications:

1. Accuracy: Servo gearboxes provide exceptional accuracy in speed and position control, making them suitable for applications that require tight tolerances and precise movements.

2. Low Backlash: These gearboxes are designed to minimize backlash, which is essential for eliminating lost motion and ensuring accurate positioning.

3. High Torque Density: Servo gearboxes offer a high torque-to-size ratio, allowing them to handle significant loads while maintaining a compact footprint.

4. Dynamic Performance: They excel in dynamic performance, enabling rapid changes in speed and direction with minimal overshoot or settling time.

5. Responsiveness: Servo gearboxes respond quickly to control signals, making them ideal for applications that require rapid adjustments and changes in direction.

6. Smooth Operation: These gearboxes provide smooth and precise movement, critical for applications like robotics, where jerky or uneven motion can lead to inaccuracies or damage.

7. Reduces Maintenance: The accuracy and durability of servo gearboxes can reduce wear and tear on other components, leading to lower maintenance requirements.

8. Improved Efficiency: Servo gearboxes offer high efficiency in power transmission, contributing to energy savings and minimizing heat generation.

9. Customization: They can be tailored to specific application needs, including factors like reduction ratios, mounting options, and feedback compatibility.

10. Versatility: Servo gearboxes find application in various industries, including robotics, CNC machining, medical equipment, and automation.

Overall, the benefits of using a servo gearbox for precise motion control make them an essential component in applications that demand accuracy, responsiveness, and reliable performance.

editor by CX 2024-05-13

China factory High Precision High Torque Durable Servo Motor Planetary Robot Gear Box Flange Reducer Helical Gearbox for 52 Stepping Motor gearbox and motor

Product Description

| Product name | Precision Planetary Reducer |

| Model No. | AB42-AB220 |

| Layout form | Planetary structure |

| Speed ratio | 3-512 |

| Output torque | 20-1500N.M |

| Power | 50W~30KW |

| Input speed | 0~4000RPM |

| Output speed | 0~1300RPM |

| Output type | Shaft type |

| Installation | Flange mounting |

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Industries Utilizing Servo Gearboxes

Servo gearboxes find applications in various industries where precise motion control is essential:

1. Robotics and Automation: Servo gearboxes are widely used in robotics and automation systems for accurate and dynamic movement control, enhancing the performance of industrial robots, collaborative robots (cobots), and other automated machinery.

2. Aerospace and Aviation: The aerospace industry utilizes servo gearboxes in aircraft control systems, including ailerons, elevators, and rudders, to ensure precise and responsive flight control.

3. Medical Equipment: Medical devices and equipment, such as surgical robots, diagnostic instruments, and imaging systems, rely on servo gearboxes to achieve precise and controlled movements for medical procedures and patient care.

4. Manufacturing and Assembly: Servo gearboxes are essential in manufacturing and assembly lines for tasks such as pick-and-place operations, conveyor systems, packaging machinery, and precision machining.

5. Automotive Industry: Automotive manufacturing and testing processes benefit from servo gearboxes for tasks such as vehicle assembly, quality control, and testing systems.

6. Semiconductor Manufacturing: High-precision processes in semiconductor manufacturing, including wafer handling and positioning, utilize servo gearboxes to maintain accuracy in microchip fabrication.

7. Material Handling: Servo gearboxes play a role in material handling systems, such as automated guided vehicles (AGVs), palletizers, and cranes, ensuring smooth and controlled movement of goods.

8. Entertainment and Theme Parks: Roller coasters, animatronics, and other entertainment attractions utilize servo gearboxes to create dynamic and engaging experiences for visitors.

9. Textile Industry: Servo gearboxes are used in textile machinery for processes like spinning, weaving, and knitting, enabling precise control of thread tension and fabric movement.

10. Research and Development: In research settings, servo gearboxes are employed for experimentation, testing, and prototyping of mechanical systems and prototypes.

Servo gearboxes provide the necessary precision, flexibility, and reliability required in these industries, enabling advanced motion control and enhancing the efficiency and performance of various applications.

editor by CX 2023-10-08

China Good quality High Precision Rotary Flange Planetary Gearbox High-Precision Gear Reducer Low Backlash Precision Gearboxes High Precision Servo Mount Gearboxes synchromesh gearbox

Product Description

Product Features

* Compact structure, integration of alloy aluminum body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface.

* The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load, allowable hith torque output.

* Gear is made of high strength alloy steel carburizing, grinding precision.

* The design of multiple alloy steel output and input shaft applies to various industrial requirements.

* The simplified structure design with high torque and low backlash applies to applications of precision servo.

* Easy mount, with maintenance-free, no need to replace the grease and long service life.

* Application in Precision Rotary Axis Drives, Travel Gantry and Columns, Material Handling Axis Drives, Industrial Areas in Automation, Aerospace, and Machine Tool and Robotics.

Product Description

Shaft Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-C Series: Shaft Input Configuration, and Hollow Output Shaft with Two Shrinks Discs.

* Models: JAC065C, JAC075C, JAC090C, JAC0110C, JAC0140C, JAC0170C, JAC210C.

* JAC-H Series: Shaft Input Configuration, and Hollow Output Shaft with Key Way.

* Models: JAC065H, JAC075H, JAC090H, JAC0110H, JAC0140H, JAC0170H, JAC210H.

* JAC-L Series: Shaft Input Configuration, and Solid Output Shaft.

* Models: JAC065L, JAC075L, JAC090L, JAC0110L, JAC0140L, JAC0170L, JAC210L.

* Gear Ratios: Spiral bevel gear set of high precision grinding can achieve from 1:1 to 6:1 as standard.

* Stage: 1 stage (1:1 to 6:1).

* Rated Output Torque (N.m): From 12N.m to 1300N.m.

* Fault Stop Torque = 2 Times of Rated Output Torque.

* Max. Input Speed (rpm): From 2500RPM to 3500RPM.

* Rated Input Speed (rpm): From 1500RPM to 2500RPM.

* Low Backlash (arcmin): From 6 arcmin to 8 arcmin.

* Max. Radial Force (N) Of Output Shaft: From 900N to 11500N.

* Max. Axial Force (N) Of Output Shaft: From 450N to 5750N.

* Max. Radial Force (N) Of Input Shaft: From 700N to 7800N.

* Max. Axial Force (N) Of Input Shaft: From 350N to 3900N.

* Low Noise Level (dB): From 71dB to 82dB.

* High Efficiency (%): 98%.

* Average Life Span (hr): 20000 hours.

* Lubrication: Synthetic lubrication grease

* Mass Moments of Inertia (kg/cm2): From 0.43 kg/cm2 to 195.4 kg/cm2.

Motor Flange Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-FC Series: Motor Flange Input Configuration, and Hollow Output Shaft with Two Shrinks Discs.

* Models: JAC065FC, JAC075FC, JAC090FC, JAC0110FC, JAC0140FC, JAC0170FC, JAC210FC.

* JAC-FH Series: Motor Flange Input Configuration, and Hollow Output Shaft with Key Way.

* Models: JAC065FH, JAC075FH, JAC090FH, JAC0110FH, JAC0140FH, JAC0170FH, JAC210FH.

* JAC-FL Series: Motor Flange Input Configuration, and CZPT Output Shaft.

* Models: JAC065FL, JAC075FL, JAC090FL, JAC0110FL, JAC0140FL, JAC0170FL, JAC210FL.

* Gear Ratios: Spiral bevel gear set of high precision grinding can achieve from 1:1 to 100:1 as standard, custom-made max. 400:1 ratio.

* Stage: 1 stage (1:1 to 6:1), 2 stage (8:1 to 30:1), 3 stage (32:1 to 100:1).

* Rated Output Torque (N.m): From 12N.m to 1300N.m.

* Fault Stop Torque = 2 Times of Rated Output Torque.

* Max. Input Speed (rpm): From 2000RPM to 5000RPM.

* Rated Input Speed (rpm): From 1500RPM to 2500RPM.

* Low Backlash (arcmin): From 6 arcmin to 15 arcmin.

* Max. Radial Force (N) Of Output Shaft: From 900N to 11500N.

* Max. Axial Force (N) Of Output Shaft: From 450N to 5750N.

* Low Noise Level (dB): From 71dB to 82dB.

* High Efficiency (%): From 94% to 98%.

* Average Life Span (hr): 20000 hours.

* Mass Moments of Inertia (kg/cm2): From 0.15 kg/cm2 to 195.4 kg/cm2.

Product Parameters

Shaft Input Configuration – High Precision Spiral Bevel Gearboxes

Motor Flange Input Configuration – High Precision Spiral Bevel Gearboxes

Product Dimensions

Shaft Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-C Series: Shaft Input Configuration, and Hollow Output Shaft with Two Shrinks Discs.

* Models: JAC065C, JAC075C, JAC090C, JAC0110C, JAC0140C, JAC0170C, JAC210C.

Shaft Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-H Series: Shaft Input Configuration, and Hollow Output Shaft with Key Way.

* Models: JAC065H, JAC075H, JAC090H, JAC0110H, JAC0140H, JAC0170H, JAC210H.

Shaft Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-L Series: Shaft Input Configuration, and Solid Output Shaft.

* Models: JAC065L, JAC075L, JAC090L, JAC0110L, JAC0140L, JAC0170L, JAC210L.

Motor Flange Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-FC Series: Motor Flange Input Configuration, and Hollow Output Shaft with Two Shrinks Discs.

* Models: JAC065FC, JAC075FC, JAC090FC, JAC0110FC, JAC0140FC, JAC0170FC, JAC210FC.

Motor Flange Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-FH Series: Motor Flange Input Configuration, and Hollow Output Shaft with Key Way.

* Models: JAC065FH, JAC075FH, JAC090FH, JAC0110FH, JAC0140FH, JAC0170FH, JAC210FH.

Motor Flange Input Configuration – High Precision Spiral Bevel Gearboxes

* JAC-FL Series: Motor Flange Input Configuration, and CZPT Output Shaft.

* Models: JAC065FL, JAC075FL, JAC090FL, JAC0110FL, JAC0140FL, JAC0170FL, JAC210FL.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right-Angle, 90 Degree |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | 1-Stage, 2-Stage, 3-Stage |

| Customization: |

Available

| Customized Request |

|---|

Compatibility of Servo Gearbox with a Specific Motor

The compatibility between a servo gearbox and a specific motor depends on several key factors:

1. Mounting Configuration: The mounting interface of the servo gearbox and motor must be compatible. This includes the type of coupling, flange size, and bolt pattern. Proper alignment ensures efficient power transmission and minimizes mechanical stress.

2. Shaft Diameter and Keyway: The diameter and keyway of the motor shaft must match the input shaft of the servo gearbox. A precise fit prevents slippage and ensures accurate torque transmission.

3. Torque and Speed Ratings: The torque and speed requirements of the application should align with the torque and speed ratings of both the motor and gearbox. Oversizing or undersizing either component can lead to inefficient operation and premature wear.

4. Inertia Matching: Inertia matching between the motor and gearbox helps prevent resonance and oscillations in the system. An appropriate inertia match ensures smooth and precise motion control.

5. Backlash and Stiffness: The gearbox’s backlash (play in the gears) and stiffness characteristics should match the application’s requirements. Low backlash and high stiffness are crucial for accurate positioning tasks.

6. Efficiency and Heat Dissipation: The combined efficiency of the motor and gearbox affects the overall system efficiency. Inadequate efficiency can lead to energy losses and excessive heat generation.

7. Service Life and Maintenance: Compatibility also involves considering the expected service life and maintenance requirements. A well-matched motor-gearbox combination enhances the durability and reliability of the motion control system.

8. Control and Feedback: The control system’s capabilities, such as closed-loop control and feedback devices, play a role in determining compatibility. The motor and gearbox should provide the necessary interfaces for effective integration into the control system.

Manufacturers and engineers often provide guidelines and compatibility charts to assist in selecting the right servo gearbox for a specific motor. Considering these factors ensures optimal performance, efficiency, and longevity of the motion control system.

Considerations for Selecting the Right Servo Gearbox for an Application

Choosing the appropriate servo gearbox for a specific application requires careful evaluation of several key factors:

1. Torque and Speed Requirements: Determine the required torque and speed characteristics of the application, ensuring that the chosen servo gearbox can provide the necessary output.

2. Gear Ratio: Calculate the ideal gear ratio based on the desired motion profile, acceleration, and deceleration requirements.

3. Mounting and Integration: Consider the available space and mechanical layout of the machinery to choose a servo gearbox with the appropriate mounting configuration.

4. Motor Compatibility: Ensure that the servo gearbox is compatible with the specific type and size of motor being used for the application.

5. Precision and Accuracy: Evaluate the level of precision required for the application’s motion control. Choose a servo gearbox that can deliver the necessary accuracy and repeatability.

6. Load Distribution: Analyze how the load will be distributed among the gears to prevent excessive wear and ensure optimal performance.

7. Backlash and Compliance: Consider the application’s tolerance for backlash and compliance. Choose a servo gearbox with low backlash if precise positioning is essential.

8. Environmental Conditions: Factor in the environmental conditions of the application, such as temperature, humidity, and exposure to contaminants. Choose a servo gearbox with suitable sealing and protection.

9. Lubrication: Determine the lubrication requirements of the gearbox and select a model that aligns with the application’s maintenance practices.

10. Overload and Shock: Consider potential overload and shock conditions the gearbox may experience. Choose a servo gearbox that can handle sudden changes in load without compromising performance.

11. Feedback Devices: If precise motion control is required, choose a servo gearbox that is compatible with the desired feedback devices, such as encoders or resolvers.

12. Efficiency: Evaluate the efficiency of the servo gearbox to ensure that it contributes to the overall energy efficiency of the system.

13. Service and Support: Select a reputable manufacturer that offers reliable technical support, documentation, and post-purchase services.

14. Budget: Balance the performance requirements of the application with the available budget to make an informed decision.

By carefully considering these factors, engineers and designers can confidently choose the right servo gearbox that meets the specific needs of their application, optimizing performance and productivity.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2023-09-05

China OEM Nmrv 110 Aluminum Material Worm Speed Reducer Gearbox Flange Mounted wholesaler

Product Description

Nmrv 110 Aluminum Material Worm Speed Reducer Gearbox Flange mounted

|

Input Configurations |

Double or single input shaft (NRV) |

|

PAM / IEC motor input shaft with circle or square flange (NMRV) |

|

|

Output Configurations

|

Double or single output shaft |

|

Output flange |

Technical Data:

| Housing material | Cast iron/Ductile iron |

| Housing hardness | HBS190-240 |

| Gear material | 20CrMnTi alloy steel |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Input / Output shaft material | 42CrMo alloy steel |

| Input / Output shaft hardness | HRC25~30 |

| Machining precision of gears | accurate grinding, 6~5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | tempering, cementiting, quenching, etc. |

| Efficiency | 94%~96% (depends on the transmission stage) |

| Noise (MAX) | 60~68dB |

| Temp. rise (MAX) | 40°C |

| Temp. rise (Oil)(MAX) | 50°C |

| Vibration | ≤20µm |

| Backlash | ≤20Arcmin |

| Brand of bearings | China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, NSK. |

| Brand of oil seal | NAK — ZheJiang or other brands requested |

Main applied for

Harbor and shipping

Hoist and transport

Electric power

Coal mining

Cement and construction

Paper and light industry

Specification

|

Model |

Motor Input Flange (circle) |

Transmission Ratio |

Power (kw) |

Ratio (i) |

Nominal Torque (Nm) |

|||||||||||||||

|

PAM / IEC |

Internal Dia. |

Dis. Between Diagonal Screw Holes |

External Dia. |

Width of Key Slot |

5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

80 |

100 |

||||

|

N |

M |

P |

E |

Diamter of Input Shaft |

||||||||||||||||

|

NMRV25 |

56B14 |

50 |

65 |

80 |

3 |

9 |

– |

9 |

– |

0.06 |

7.5-60 |

2.6-14 |

||||||||

|

NMRV30 |

63B5 |

95 |

115 |

140 |

4 |

11 |

– |

0.06-0.18 |

7.5-80 |

2.6-14 |

||||||||||

|

63B14 |

60 |

75 |

90 |

|||||||||||||||||

|

56B5 |

80 |

100 |

120 |

3 |

9 |

– |

||||||||||||||

|

56B14 |

50 |

65 |

80 |

|||||||||||||||||

|

NMRV40 |

71B5 |

110 |

130 |

160 |

5 |

14 |

– |

0.09-0.37 |

7.5-100 |

11-53 |

||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

63B5 |

95 |

115 |

140 |

4 |

11 |

|||||||||||||||

|

63B14 |

60 |

75 |

90 |

|||||||||||||||||

|

56B5 |

80 |

100 |

120 |

3 |

– |

9 |

||||||||||||||

|

NMRV50 |

80B5 |

130 |

165 |

200 |

6 |

19 |

– |

0.12-0.75 |

7.5-100 |

21-89 |

||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

5 |

14 |

– |

||||||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

63B5 |

95 |

115 |

140 |

4 |

– |

11 |

||||||||||||||

|

NMRV63 |

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

0.25-1.5 |

7.5-100 |

56-166 |

||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

19 |

– |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

5 |

– |

14 |

||||||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

NMRV75 |

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

– |

0.55-4 |

7.5-100 |

90-269 |

|||||||||

|

100/112B14 |

110 |

130 |

160 |

|||||||||||||||||

|

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

– |

19 |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

– |

– |

14 |

||||||||||||||

|

NMRV90 |

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

– |

0.55-4 |

7.5-100 |

101-458 |

|||||||||

|

100/112B14 |

110 |

130 |

160 |

|||||||||||||||||

|

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

– |

19 |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

NMRV110 |

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

1.1-7.5 |

7.5-100 |

242-660 |

|||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

28 |

– |

||||||||||||||

|

90B5 |

130 |

165 |

200 |

– |

24 |

|||||||||||||||

|

90B14 |

95 |

115 |

140 |

– |

||||||||||||||||

|

80B5 |

130 |

165 |

200 |

– |

19 |

|||||||||||||||

|

NMRV130 |

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

2.2-7.5 |

7.5-100 |

333-1596 |

|||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

||||||||||||||

|

90B5 |

130 |

165 |

200 |

– |

– |

24 |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

NMRV150 |

160B5 |

250 |

300 |

350 |

12 |

– |

42 |

– |

2.2-15 |

7.5-100 |

570-1760 |

|||||||||

|

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

|||||||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

||||||||||||||

Company profile

Scenario

Packing

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P etc.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power,output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings,it is nice.

Q4: If we don’t find what we want on your website, what should we do?

A: We offer 3 options:

1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our

standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for RV series worm gearbox, 35-40 workdays for helical gearmotors.

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | B3,B6,B7,B8,V5,V6 |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Can a Worm Gearbox Provide High Torque Output?

Yes, a worm gearbox is capable of providing high torque output due to its unique design and principle of operation. Worm gears are known for their high torque multiplication capabilities, making them suitable for applications that require significant torque transfer.

The torque output of a worm gearbox is influenced by several factors:

- Lead Angle: The lead angle of the worm affects the mechanical advantage of the gear system. A larger lead angle can result in higher torque output.

- Worm Diameter: A larger diameter worm can offer increased torque output as it provides more contact area with the gear.

- Gear Ratio: The gear ratio between the worm and the gear determines the torque multiplication factor. A higher gear ratio leads to higher torque output.

- Lubrication: Proper lubrication is essential to minimize friction and ensure efficient torque transmission.

- Material and Quality: High-quality materials and precision manufacturing contribute to the gearbox’s ability to handle high torque loads.

Due to their ability to provide high torque output in a compact form factor, worm gearboxes are commonly used in various industrial applications, including heavy machinery, construction equipment, conveyor systems, and more.

editor by CX 2023-08-23

China Eed Transmission Worm Gearbox E-RV050 with Input Flange worm gear reducer buy

Merchandise Description

Overview

———————————————————————————————————————————————————————————————————————————————–

Fast Particulars

Gearing Arrangement: Worm Brand Identify: EED

Input Velocity: 1400 rpm Output Velocity: 14 rpm to 186 rpm

Rated Electricity: .06 ~ 4KW Output Torque: 2.6-479N.M

Coloration: Blue/Silver or on request Origin: ZHangZhoug, China (Mainland)

Guarantee: 1 Year Application: Market

———————————————————————————————————————————————————————————————————————————————–

Offer Capacity

Offer Capacity: 20000 Piece/Pieces for every Thirty day period

Further Support: OEM is welcome

QC Program: ISO9001:2008

———————————————————————————————————————————————————————————————————————————————–

Packaging & Shipping and delivery

Bundle: Wooden box/Paper carton

Port: HangZhou/ZheJiang or on request

———————————————————————————————————————————————————————————————————————————————–

| Sort | Worm Equipment Speed Reducer/Worm Gearbox |

| Design | NMRV series measurement:571,030,040,050,063,075,090,one hundred ten,one hundred thirty,one hundred fifty |

| RATIO | five,7.5,ten,fifteen,twenty,twenty five,thirty,40,fifty,sixty,80,a hundred |

| Shade | Blue(RAL5571)/Silver gray (RAL9571) or on your ask for |

| Content | Housing:Aluminum alloy |

| PACKING | Picket box/Paper carton |

| BEARING | C&U |

| SEAL | SKF |

| Warranty | one Yr |

| Input Power | .09KM-15KM |

| USAGES | Foodstuffs, Ceramics, Packing, Substances, Pharmacy, Plastics, Paper-producing, Machine-resources |

| IEC FLANGE | IEC regular flange or on request |

| LUBRICANT | Shell or Henry |

About CZPT since 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism field and punching/stamping subject because 1984. Our principal item, NMRV worm equipment velocity reducer and series helical gearbox, XDR, XDF, XDK, XDS have arrived at the superior strategy index of the congeneric European and Janpanese goods. We supply common gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders of non-standard goods, this kind of as gears, shafts, punching areas ect, according to customers’ drawings or samples.

Our business has total established of gear like CNC, lathes, milling devices, equipment hobbing equipment, gear grinding machine, gear honing machine, gear shaping machine, worm grinder, grinding equipment, drilling equipment, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing devices and so on. We have superior screening equipments as nicely.

Our organization has recognized favorable cooperation associations with sub-suppliers involving casting, uncooked substance, heat remedy, surface ending and so on.

The most gain of the pace reducer is the technique of cobber clad, which can improve the occlusal force among the bronze and core wheel.

|

US $10-500 / Piece | |

10 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Step: | Single-Step |

| Type: | Worm Reducer |

| Transport Package: | Shrink Packing, Carton Packing |

| Trademark: | OEM; EED |

###

| Customization: |

Available

|

|---|

###

| TYPE | Worm Gear Speed Reducer/Worm Gearbox |

| MODEL | NMRV series size:025,030,040,050,063,075,090,110,130,150 |

| RATIO | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| COLOR | Blue(RAL5010)/Silver grey (RAL9022) or on your request |

| MATERIAL | Housing:Aluminum alloy |

| PACKING | Wooden box/Paper carton |

| BEARING | C&U |

| SEAL | SKF |

| WARRANTY | 1 Year |

| INPUT POWER | 0.09KM-15KM |

| USAGES | Foodstuffs, Ceramics, Packing, Chemicals, Pharmacy, Plastics, Paper-making, Machine-tools |

| IEC FLANGE | IEC standard flange or on request |

| LUBRICANT | Shell or Henry |

|

US $10-500 / Piece | |

10 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Step: | Single-Step |

| Type: | Worm Reducer |

| Transport Package: | Shrink Packing, Carton Packing |

| Trademark: | OEM; EED |

###

| Customization: |

Available

|

|---|

###

| TYPE | Worm Gear Speed Reducer/Worm Gearbox |

| MODEL | NMRV series size:025,030,040,050,063,075,090,110,130,150 |

| RATIO | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| COLOR | Blue(RAL5010)/Silver grey (RAL9022) or on your request |

| MATERIAL | Housing:Aluminum alloy |

| PACKING | Wooden box/Paper carton |

| BEARING | C&U |

| SEAL | SKF |

| WARRANTY | 1 Year |

| INPUT POWER | 0.09KM-15KM |

| USAGES | Foodstuffs, Ceramics, Packing, Chemicals, Pharmacy, Plastics, Paper-making, Machine-tools |

| IEC FLANGE | IEC standard flange or on request |

| LUBRICANT | Shell or Henry |

Worm reducer gearbox

Worm reducer gearboxes are commonly used to reduce the Agknx produced by a rotating shaft. They can achieve reduction ratios of five to sixty. In contrast, a single-stage hypoid gear can achieve up to a 120:1 reduction ratio. For further reduction, another type of gearing is used. So, a single stage worm reducer gearbox cannot achieve higher ratios than these.<br

Mechanics

A worm reducer gearbox is an auxiliary mechanical device that uses worms to reduce the size of a rotating shaft. These worms have a range of tooth forms. One form is a line weave twist surface. Another is a trapezoid based on a central cross section. The trapezoid can be perpendicular to the tooth cross section, or it can be normal to the root cross section. Other forms include involute helicoids and convolute worms, which use a straight line intersecting the involute generating line.

Worm gears are lubricated with a special lubricant. Because worm gears are complex, it’s important to use the correct lubricant. Worm gear manufacturers provide approved lubricants for their gears. Using unapproved gear oil can damage your reducer gearbox’s efficiency. The right lubricant depends on several factors, including load, speed, duty cycle, and expected operating temperatures.

The efficiency of a worm gear reducer gearbox depends on several factors, including losses at gear mesh, losses in the bearings, and windage in the oil seal lip. In addition, the worm gear reducer gearbox’s efficiency varies with ambient temperature and operating temperature. The worm gear reducer gearbox’s efficiency can also vary with the ratio of the load. Moreover, worm gear reducer gearboxes are subject to break-in.

Worm gear reducer gearboxes are used in many different applications. They are typically used in small electric motors, but they’re also used in conveyor systems, presses, elevators, and mining applications. Worm gears are also commonly found in stringed musical instruments.

Worm gears have excellent reduction ratios and high Agknx multiplication, and they’re often used as speed reducer gearboxes in low to medium-speed applications. However, the efficiency of worm gear reducer gearboxes decreases with increasing ratios.

Sizes

Worm reducer gearboxes come in different sizes and tooth shapes. While the tooth shape of one worm is similar to the other, different worms are designed to carry a different amount of load. For example, a circular arc worm may have a different tooth shape than one with a secondary curve. Worm gears can also be adjusted for backlash. The backlash is the difference between the advancing and receding arc.

There are two sizes of worm reducer gearboxes available from Agknx Transmission. The SW-1 and SW-5 models offer ratios of 3.5:1 to 60:1 and 5:1 to 100:1 respectively. The size of the worm reducer gearbox is determined by the required gear ratio.

Worm gears have different thread counts. One is based on the central cross-section of the worm, and the other is on the right. Worm gears can have either a single or double thread. Single-threaded gears will reduce speed by 50 percent, while double-threaded gears will reduce speed by 25 percent.

Worm gear reducer gearboxes are lightweight and highly reliable. They can accommodate a variety of NEMA input flanges and hollow output bore sizes. Worm reducer gearboxes can be found at 6 regional warehouses, with prepaid freight. To make a purchasing decision, you should consider the horsepower and Agknx requirements of your specific application.

Applications

The Worm reducer gearbox market is a global business that is dominated by the North American and European regions. The report provides in-depth information on the market trends, key challenges, and opportunities. It also examines the current state of the industry and projects future market growth. The report is organized into segments based on product type, major geographical regions, and application. It also presents statistics and key data about the market.

Worm gear reducer gearboxes have many applications. They can be used to increase the speed of convey belts. They also help reduce noise. Worm gears have many teeth that touch the gear mesh, which makes them quieter. Moreover, the worm gears require only a single stage reducer gearbox, reducing the number of moving parts in the system.

The worm gear has long life and is suitable for different industries. It is a perfect choice for elevators and other applications that need fast stopping and braking. Its compact size and ability to hold a load make it suitable for these applications. It also prevents the load from free-falling as a result of a sudden braking. Worm gears can also be used in heavy-duty machinery such as rock crushers.

Worm gears are similar to ordinary gears except that they transfer motion at a 90-degree angle. As a result, the worm gears are extremely quiet, making them a suitable option for noise sensitive applications. They are also excellent for low-voltage applications, where the noise is critical.

Worm gears are ideal for applications with space restrictions, because they require fewer gear sets. The worm gears also allow for a smaller gearbox size. Consequently, they are the perfect choice for machines that are space-constrained, such as conveyors and packaging equipment.

Cost

The lifespan of a worm gear reducer gearbox is comparable to other gear reducer gearboxes. Worm gears have a long history of innovation and use in various industries, from shipbuilding to automobile manufacturing. Today, these gear reducer gearboxes are still popular with engineers. However, there are some things to keep in mind before buying one.

In the first place, a worm reducer gearbox needs to be affordable. Generally, a worm reducer gearbox costs about $120. The price varies with the brand name and features. Some products are more expensive than others, so be sure to shop around for the best price. In addition, it is important to consider the quality and design of the worm reducer gearbox before making a purchase.

Worm gear manufacturers have made significant advancements in materials, design and manufacturing. These advancements, along with the use of advanced lubricants, have resulted in significant increases in efficiency. For example, double enveloping worm gear reducer gearboxes have improved efficiency by three to eight percentage points. This improvement was achieved through rigorous testing of manufacturing processes and materials. With these improvements, worm gear reducer gearboxes have become more desirable in today’s market.

Worm reducer gearboxes are extremely versatile and reliable, and are available in a variety of sizes. Domestic manufacturers usually stock a large selection of reducer gearboxes, and are often able to ship them the same day you place your order. Most major domestic worm gear reducer gearbox manufacturers also share some critical mounting dimensions, such as the output shaft diameter, the mounting hole location, and the overall reducer gearbox housing height. Most manufacturers also offer standardized gear ratios. Some manufacturers have also improved gear design and added synthetic lubricants for better performance.

In addition, different tooth shapes of worms can increase their load carrying capacity. They can be used on secondary curves and circular arc cross sections. Moreover, the pitch point defines the boundary of the cross section. The mesh on the receding arc is smoother than that of the advancing arc. However, in the case of negative shifting, most of the mesh is on the receding arc.

Self-locking function

A worm reducer gearbox has a self-locking function. When a worm is fitted with all of its addendum teeth, the total number of teeth in the system should be greater than 40. This self-locking function is achieved through the worm’s rack and pinion mechanism. The worm’s self-locking feature can prevent the load from being dropped and is useful for many applications.

The self-locking function of a worm reducer gearbox is possible for two main reasons. First of all, a worm reducer gearbox uses two or more gears. One gear is placed at the input, and the other gear runs the output shaft. This mechanism produces a torque, which is transmitted to a spur gear.

Worm reducer gearboxes can be used in a variety of industrial applications. Because of their self-locking function, they are useful for preventing back-driving. They are also helpful for lifting and holding loads. Their self-locking mechanism allows for a large gear reduction ratio without increasing the size of a gear box.

Self-locking gears can be used to prevent back-driving and inertial driving. This is useful for many industries and can prevent backdriving. However, one major disadvantage of self-locking gears is their sensitivity to operating conditions. Lubrication, vibration, and misalignment can affect their reliability.

Embodiments of the invention provide a self-locking mechanism that prevents back-driving but allows forward-driving. The self-locking mechanism may comprise first and second ratchet cams disposed about a gear member. A releasable coupling member may be interposed between the gear member and the ratchet cam. This facilitates selective coupling and decoupling.

The worm reducer gearbox has several advantages. Its compact design is ideal for many mechanical transmission systems. It also provides greater load capacity than a cross-axis helical gear mechanism.

editor by czh 2022-12-16

in Bologna Italy sales price shop near me near me shop factory supplier Atg High Stability Speed Flange Planetary Reducer manufacturer best Cost Custom Cheap wholesaler

We also can design and make non-standard products to satisfy customers’ specific specifications. With a lot of years’ encounter in this line, we will be dependable by our advantages in competitive price, one particular-time shipping, prompt reaction, on-hand engineering support and good soon after-income companies.Additionally, all our generation techniques are in compliance with ISO9001 standards. EPG has been effectively qualified by ISO9002 Quality Administration Method, ISO9001 Top quality Administration Program, API certification, ISO/TS16949:2002 and ISO10012 measurement administration technique. PGE Series

Merchandise Characteristics:

(one) Minimal Noise:UnEPTT65db.

(two) Low Backlash:Backlash is unEPTT3 arcmin . Backlash for two-phase pace reduction is with in 5 arcmin.

(three) Higher Performance:1-phase up to 95% or much more,two-phase up to 92% or a lot more.

(4) Substantial Enter Velocity:Enter speed makes it possible for for up to 8000RPM.

(five) Large Torque:Substantial torque output than that of conventional planetary EPTT EPTTs

(6) Servicing-Free of charge:Reduced grease put on,can be life span lubrication

(7) High Pace Reduction Ratio:Velocity ratio is over 1/1000.

Edge:

Use:

- Aerospace,armed forces business.

- Healthcare wellness,digital data sector.

- Market robots,Production EPTT,CNC EPTT resource manufacturing industry.

- EPTT,Textile,EPTT,Foods,EPTTlurgical.

- EPTT defense engineering,Warehouse EPTT business.

Design ILLUMINATE:

Equipment BOX Overall performance Data:

| MODUL NO. | Phase | RATIO sup1 | PGE42 | PGE60 | PGE90 | PGE120 | PGE160 | |

| Rated output torque T2N | Nm | one | three | 14 | 39 | 104 | 215 | 423 |

| 4 | twelve | 31 | 85 | 176 | 364 | |||

| five | fourteen | 39 | 104 | 215 | 423 | |||

| 7 | 12 | 33 | 91 | 195 | 358 | |||

| eight | ten | 33 | 80 | one hundred sixty | 330 | |||

| ten | nine | 28 | seventy five | 210 | 320 | |||

| 12 | fourteen | 39 | 104 | 215 | 423 | |||

| fifteen | 14 | 39 | 104 | 215 | 423 | |||

| twenty | twelve | 31 | eighty five | 176 | 364 | |||

| twenty five | 14 | 39 | 104 | 215 | 423 | |||

| thirty | – | – | 104 | 215 | 423 | |||

| 35 | 14 | 39 | 104 | 215 | 423 | |||

| 40 | 14 | 39 | 104 | 215 | 423 | |||

| 50 | – | – | 104 | 215 | 423 | |||

| 70 | – | – | 104 | 215 | 423 | |||

| one hundred | 9 | 28 | 75 | 210 | 320 | |||

| 3~100 | 3 times of Nominal Output Torque | |||||||

| 3~one hundred | 450 | four,000 | 3,600 | three,000 | 2,five hundred | |||

| 3~100 | 800 | 6,000 | six,000 | four,800 | 3,600 | |||

| EPTT Backlash | arcmin | 1 | 3~10 | le8 | ||||

| two | 12~one hundred | le10 | le10 | le8 | le8 | le8 | ||

| Torsional stiffness | Nm/arcmin | one,2 | three~a hundred | one | two | 7 | 15 | 66 |

| Max.radial drive F2rB sup2 | N | one,2 | three~100 | three hundred | 680 | 1750 | 3080 | 6520 |

| 1,two | 3~one hundred | 150 | 340 | 875 | 1540 | 3260 | ||

| Support life | hr | one,two | 3~one hundred | twenty,000* | ||||

| 1 | three~ten | ge97 | ||||||

| 2 | twelve~100 | ge94 | ||||||

| Weight | kg | 1 | three~10 | one | 2 | 4 | eight | 18 |

| 2 | twelve~one hundred | 1 | 2 | five | eleven | twenty five | ||

| Working temperature | ordmC | 1,2 | three~a hundred | -ten ordmC~ 90 ordmC | ||||

| Lubrication | one,2 | 3~a hundred | Artificial lubricating oil | |||||

| Protection amount | 1,two | 3~one hundred | IP65 | |||||

| 1,2 | 3~one hundred | Any direction | ||||||

| Sounds level(n1=3000rpm) | dB | 1,two | three~100 | le68 | le70 | le72 | le74 | le75 |

Define DIMENSION:

Organization Look at:

HangEPTT EPTEPTTn De Yi EPT Co.,Ltd. is a subsidiary of EPTTiwan Jun Yi EPTTry. Jun Yi EPTTry was established in March 1972. The firm EPTTizes in the design and style, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and creation of high-tech numerous EPTTed motors and helical EPTT EPTTs, worm and worm EPTT EPTTs and planetary EPTTs. Our items sold to more than 30 countries around the planet and win excellent track record and many awards in the overEPTT market place for numerous several years. In latest several years, to achieve EPTT generation and give excellent support,we established up subsidiary of manufacturing of planetary EPTT EPTT in EPTT.

Background:

1972:EPTTiwan Jun Yi EPTTry is founded.

1989:It estabEPTTd a overEPTT branch firm ATRUMP EPTTRY INC in Los Angeles

1995:Go the ISO9002 Commodity certification.

2003:Go the ISO9001 quality certification and the European CE stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd test which enabled the products to be offered in Europe

2013:The business set up subsidiary in EPTT to obtain EPTT manufacturing.

Factory:

Wisdom Produced IN ATG,Knowledge THE EPTT.

Gear:

INSPECTION Equipment:

FAQ:

(one) Can I be your agent?

Indeed, welcome to deep cooperation. We have massive marketing of ATG model in the marketplace now. For the specifics please make contact with me.

(two) Is OEM accessible?

Yes, OEM is offered. We have specialist designer to assist your manufacturer marketing.

(3) How can I get a sample to examine your quality?

Right after cost confirmation, you can call for for samples to check out our good quality. Free for the samples, but you need to have to shell out for the freight.

(four)What’s your good quality guarantee?

We have various varieties of merchandise which can meet up with distinct good quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Our QC section will examination goods before shipping. We have a hundred% good quality ensure to buyers. We will be dependable for any quality difficulty.

(five) How about the delivery time?

The delivery time is relying on the merchandise and the quantity. But EPTTly, the delivery time for a container is about a single month.

Welcome to our business.

If any difficulty, come to feel cost-free to depart information on the base of this page.

in Diyarbakir Turkey sales price shop near me near me shop factory supplier Atg Customized Square Housing with Flange Planetary Gear Reducer manufacturer best Cost Custom Cheap wholesaler

With many years’ knowledge in this line, we will be dependable by our positive aspects in aggressive price, a single-time supply, prompt reaction, on-hand engineering support and excellent soon after-income services.Additionally, all our creation procedures are in compliance with ISO9001 expectations. If you are interested in any of our items or would like to talk about a prospective buy, you should really feel free of charge to speak to us. With EPG model registered in a lot more than 70 international locations like The usa , Europe , Japan and so on, it has companions amid planet best enterprises, this kind of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so on. PGL Sequence

Merchandise Attributes:

(one) Reduced Sound:UnEPTT65db.

(2) Reduced Backlash:Backlash is unEPTT3 arcmin . Backlash for 2-phase speed reduction is with in five arcmin.

(three) Substantial Effectiveness:1-phase up to ninety five% or much more,2-phase up to ninety two% or far more.

(four) Substantial Input Velocity:Enter speed permits for up to 8000RPM.

(5) Substantial Torque:High torque output than that of standard planetary EPTT EPTTs

(6) Upkeep-Free of charge:Minimal grease wear,can be lifetime lubrication

(7) Large Speed Reduction Ratio:Speed ratio is above 1/1000.

Advantage:

Usage:

- Aerospace,army business.

- Health-related health,electronic info sector.

- Market robots,Generation EPTT,CNC EPTT tool production business.

- EPTT,Textile,EPTT,Foodstuff,EPTTlurgical.

- EPTT security engineering,Warehouse EPTT market.

Product ILLUMINATE:

Equipment BOX Overall performance Info:

| MODUL NO. | Stage | RATIO sup1 | PGL42 | PGL60 | PGL90 | PGL115 | PGL142 | PGL180 | PGL220 | |

| Rated output torque T2N | Nm | 1 | three | twenty | fifty five | 130 | 208 | 342 | 588 | one,140 |

| 4 | 19 | 50 | 140 | 290 | 542 | 1,050 | 1,seven-hundred | |||

| 5 | 22 | sixty | one hundred sixty | 330 | 650 | 1,two hundred | two,000 | |||

| six | twenty | 55 | one hundred fifty | 310 | 600 | one,one hundred | one,900 | |||

| 7 | 19 | 35 | a hundred and forty | 300 | 550 | one,one hundred | one,800 | |||

| eight | seventeen | 37 | one hundred twenty | 260 | 500 | one,000 | 1,600 | |||

| ten | fourteen | 55 | ninety five | 220 | 370 | 800 | one,220 | |||

| 2 | 12 | 20 | fifty five | one hundred thirty | 208 | 342 | 588 | one,140 | ||

| 15 | twenty | 50 | one hundred thirty | 208 | 342 | 588 | 1,140 | |||

| twenty | 19 | sixty | one hundred forty | 290 | 542 | one,050 | 1,700 | |||

| 25 | 22 | 60 | one hundred sixty | 330 | 650 | 1,200 | two,000 | |||

| 30 | 22 | sixty | a hundred and sixty | 330 | 650 | 1,200 | two,000 | |||

| 35 | 22 | 60 | one hundred sixty | 330 | 650 | 1,two hundred | 2,000 | |||

| 40 | 22 | 60 | one hundred sixty | 330 | 650 | one,two hundred | two,000 | |||

| 50 | 22 | sixty | 160 | 330 | 650 | one,two hundred | 2,000 | |||

| 60 | twenty | 55 | a hundred and fifty | 310 | 600 | one,a hundred | 1,900 | |||

| 70 | 19 | 35 | 140 | three hundred | fifty | 1,100 | one,800 | |||

| 80 | 17 | 35 | one hundred twenty | 260 | 500 | 1,000 | 1,600 | |||

| 100 | fourteen | 37 | ninety five | 220 | 370 | 800 | one,220 | |||

| MAX. output torqueT2B | Nm | one,two | 3~one hundred | three moments of Nominal Output Torque | ||||||

| Rated input speed n1 | rpm | one,two | 3~100 | 5,000 | five,000 | 4,000 | 4,000 | 3,000 | three,000 | two,000 |

| MAX.enter speed n1B | rpm | 1,two | three~100 | ten,000 | 10,000 | 8,000 | 8,000 | 6,000 | 6,000 | four,000 |

| EPTT Backlash P1 | arcmin | 1 | three~10 | le3 | le6 | le6 | le6 | le6 | le6 | le6 |

| 2 | twelve~a hundred | le5 | le8 | le8 | le8 | le8 | le8 | le8 | ||

| EPTT Backlash P2 | arcmin | one | 3~10 | le5 | le8 | le8 | le8 | le8 | le8 | le8 |

| two | twelve~one hundred | le7 | le10 | le10 | le10 | le10 | le10 | le10 | ||

| Torsional stiffness | Nm/arcmin | 1,2 | three~a hundred | three | 7 | fourteen | twenty five | 50 | one hundred forty five | 225 |

| Max.radial power F2rB sup2 | N | 1,2 | three~100 | 780 | 1,530 | three,250 | 6,seven-hundred | nine,four hundred | fourteen,five hundred | 50,000 |

| MAX.aXiHu (West Lake) Dis.al power F2a1B sup2 | N | one,2 | three~100 | 350 | 630 | one,300 | three,000 | four,000 | six,200 | 35,000 |

| MAX.aXiHu (West Lake) Dis.al power F2a2B sup2 | N | one,two | three~a hundred | 390 | 765 | one,625 | 3,350 | 4,seven hundred | 7,250 | twenty five,000 |

| Services existence | hr | one,two | three~a hundred | twenty,000* | ||||||

| Function effectiveness eta | % | one | three~10 | ge97 | ||||||

| two | twelve~one hundred | ge94 | ||||||||

| Fat | kg | one | three~10 | .5 | one.3 | 3.7 | seven.eight | 14.5 | 29 | 48 |

| two | 12~a hundred | .8 | one.9 | 4.1 | 9 | seventeen.5 | 33 | 60 | ||

| Running temperature | ordmC | 1,two | 3~100 | -ten ordmC~ ninety ordmC | ||||||

| Lubrication | one,2 | 3~one hundred | Synthetic lubricating oil | |||||||

| Defense level | one,two | 3~one hundred | IP65 | |||||||

| Installation course | one,2 | three~one hundred | Any direction | |||||||

| Sound stage(n1=3000rpm) | dB | one,2 | three~100 | le56 | le58 | le60 | le63 | le65 | le67 | le70 |

Define DIMENSION:

Organization Look at:

HangEPTT EPTEPTTndeyi EPTT amp EPT Co., Ltd. is a subsidiary of EPTTiwan Jun Yi EPTTry. Jun Yi EPTTry was started in March 1972. The business EPTTizes in the layout, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and creation of large-tech various EPTTed motors and helical EPTT EPTTs, worm and worm EPTT EPTTs and planetary EPTTs. Our products marketed to far more than thirty countries about the planet and get excellent reputation and numerous awards in the overEPTT marketplace for a lot of several years. In current many years, to accomplish EPTT manufacturing and give superb services,we established up subsidiary of production of planetary EPTT EPTT in EPTT.

History:

1972:EPTTiwan Jun Yi EPTTry is founded.

1989:It estabEPTTd a overEPTT department company ATRUMP EPTTRY INC in Los Angeles

1995:Move the ISO9002 Commodity certification.

2003:Pass the ISO9001 good quality certification and the European CE stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd take a look at which enabled the products to be bought in Europe

2013:The firm established up subsidiary in EPTT to attain EPTT creation.

Manufacturing unit:

Knowledge Made In ATG,Wisdom The EPTT.

Products:

INSPECTION Tools:

FAQ:

(one) Can I be your agent?

Indeed, welcome to deep cooperation. We have massive advertising of ATG model in the industry now. For the specifics make sure you speak to me.

(two) Is OEM offered?

Of course, OEM is accessible. We have specialist designer to help your manufacturer advertising.

(three) How can I get a sample to check out your top quality?

Right after cost affirmation, you can call for for samples to check our quality. Totally free for the samples, but you want to shell out for the freight.

(4)What is actually your quality assure?

We have diverse sorts of items which can meet up with different good quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Our QC office will test products just before transport. We have one hundred% good quality promise to consumers. We will be dependable for any good quality issue.

(5) How about the supply time?

The supply time is relying on the merchandise and the amount. But EPTTly, the supply time for a container is about a single month.

Welcome to our business.

If any dilemma, truly feel totally free to depart message on the base of this website page.

in Aguascalientes Mexico sales price shop near me near me shop factory supplier Wp Worm Gear Reducer Wpda with Input Flange manufacturer best Cost Custom Cheap wholesaler

our goods are marketing effectively in the American, European, South American and Asian marketplaces. PersonnelOur income people are well qualified to accommodate your requests and converse English for your ease. With EPG manufacturer registered in a lot more than 70 countries like America , Europe , Japan and so on, it has companions amongst world prime enterprises, this sort of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and many others.

gt Solution Introduction

Wpw Worm Worm Reductor

one, WP sequence worm EPTT ‘s the EPTT easy, vibration, EPTT and noise are tiny, a large reduction ratio, extensive versaEPTTty, with all kinds of mechanical equipment.

2, WPA sequence speed EPTT are capable to acquire a larger one-stage EPTT EPTT ratio, compact, most models have much better EPTT self-locking, braking specifications for mechanical equipment can save brakes

three, worm thread engagement with the worm EPTT tooth surface friction loss higher than the EPTT EPTT efficiency and consequently minimal, simple to heat and higher temperatures.

four, interworking great worm produced according to nationwide stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds, bearings, seals and so on with stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd areas. five,

5, box sort simple kind (vertical or horizontal box for two constructions with bottom foot) and the EPTT sort (box is rectangular, multi-faceted with fixed screw, not fitted with base foot or the other end foot and other structural type)

six, WP series EPTT box enter shaft coupling approaches are the basic type (one input shaft and twin enter shaft), two motor with flange.

7, WP collection EPTT ‘ output, position and route of the input shaft and the input shaft on the up coming the output aXiHu (West Lake) Dis.s and down the enter shaft and down.

eight, WP collection worm EPTT can be 2 or 3 sets consisting of multi phase EPTT EPTT to get fantastic EPTT ratio.

| Variety: | WP EPTTs reduction EPTT |

| Model: | WPA40-250 |

| Ratio: | 10,15,20,25,thirty,40,50,60 |

| Shade: | Environmentally friendly,Brown |

| EPTT: | Cast iron entire body |

| Worm Gear- Cooper-ten-3 # | |

| Worm-20CrMnTi with carburizing and quenching, surface hardness is 56-62EPTC | |

| Shaft-chromium metal-forty five# | |

| EPTT: | Paper Carton,Plywood box / for each established(With foam board within) |

| Guarantee: | one 12 months |

| Enter EPTT: | .55kw,.75kw,1.1kw,one.5kw,two.2kw,4kw,five.5kw,7.5kw |

| Usages: | In EPTT EPTT: Food stuff,Ceramics,chemical, aswell as EPTT, printing, dyeing,woodworking, EPTT and plastics #8230.. |

| IEC Flange: | 80B5,90B5,100B5,112B5,132B5…. |

| Lubricant: | Synthetic amp Mineral |

gt Catalogue

gt Our EPTT Benefits

one. Realistic cost with excellent quality

2.Each and every 1 checks cautiously

three.Obvious nameplate

four.Reliable package

5.Large effectiveness, clean runingand low sound

six.Greatest supplies make best efficiency

gt Creating Approach

gt WORKSHOP Equipment:

CERTIFICATION :

gt EPTTAGE :

for one particular container, directly loading ,for significantly less, all merchandise with pallet,

FAQ

FAQ

one, Q:what is your MOQ for ac EPTT motor ?

A: 1pc is ok for every variety electric powered EPTT box motor

2, Q: What about your warranty for your induction velocity EPTT motor ?

A: one particular year ,but besides man-manufactured ruined

3, Q: which payment way you can settle for ?

A: TT, western union .

4, Q: how about your payment way ?

A: a hundred%payment EPTTd significantly less $5000 ,30% payment EPTTd payment , 70% payment ahead of sending more than $5000.

5, Q: how about your EPTT of pace reduction motor ?

A: plywood scenario ,if measurement is modest ,we will pack with pallet for considerably less one container

6, Q: What info ought to be given, if I get electrical helical EPTTed motor from you ?

A: rated EPTT, ratio or output pace,type ,voltage , mounting way , amount , if far more is far better.

in Karaganda Kazakhstan sales price shop near me near me shop factory supplier Three Stage Round Flange Output Gearbox Ple60-350K Speed Reducer manufacturer best Cost Custom Cheap wholesaler