Product Description

Product Description

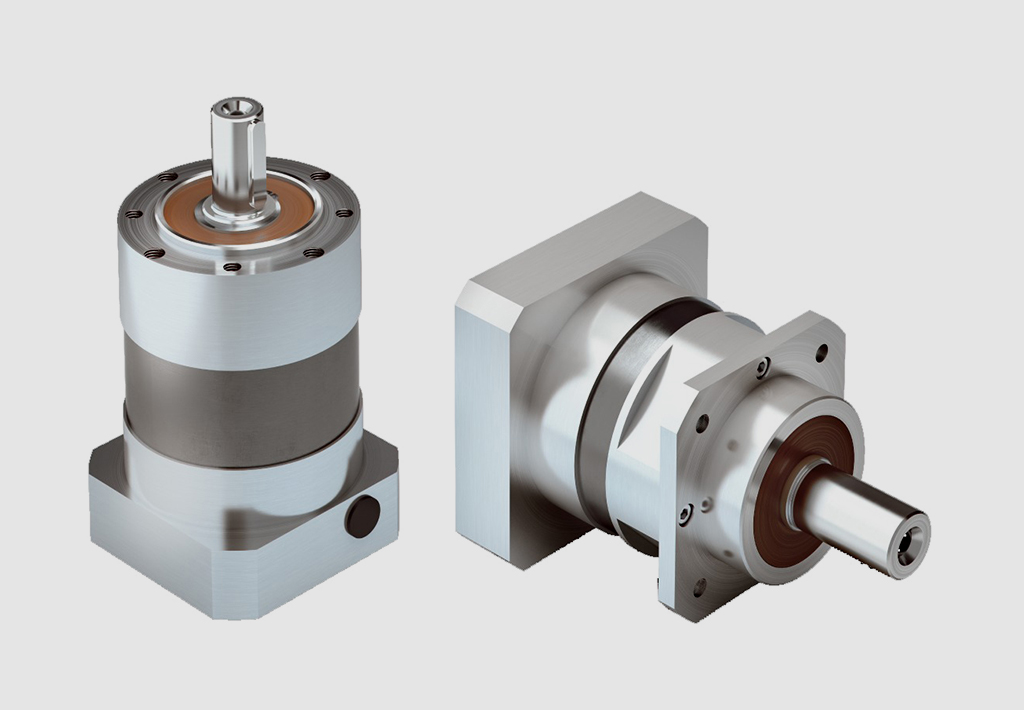

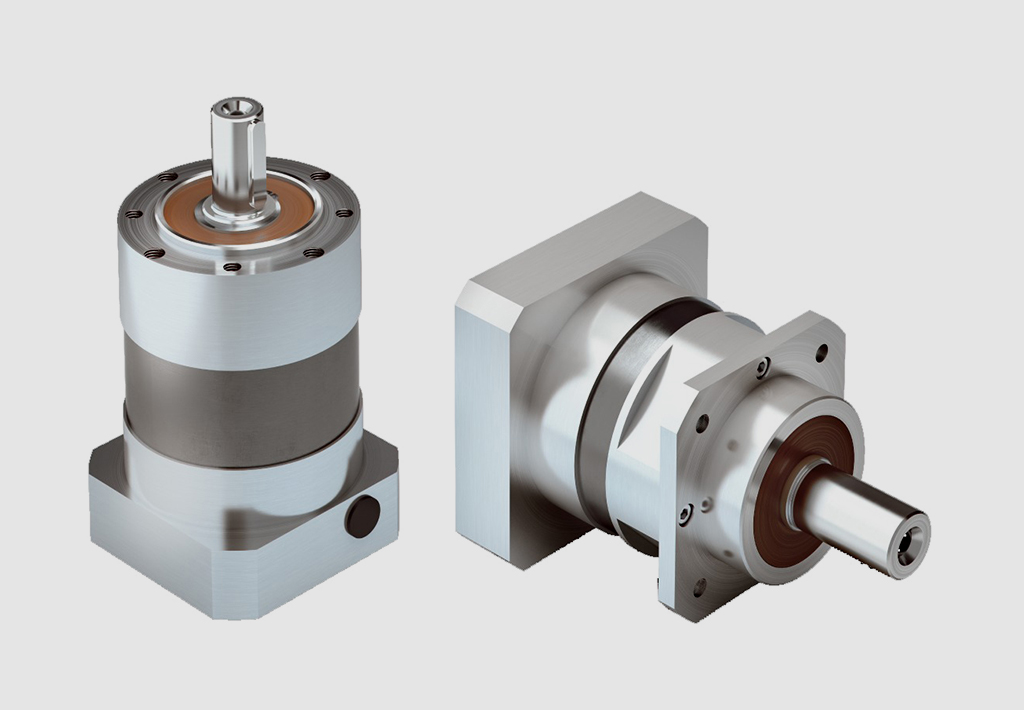

Helical Gear Motor Box PAB 42mm Speed Reducer High Speed Small Planetary Gearbox

3F PAB series high precision planetary gearbox adopts the integrated design of planet carrier and output shaft to ensure the maximum torque stiffness and stability. Several backlash types can be chosen depends on customers’ needs: Micro precision backlash (P0), precision backlash (P1) and standard backlash (P2) are available. Thanks to the high cost performance of 3F PAB series planetary gearbox, it is widely used in motion control industries for servo application. 3F PAB precision gearboxes are featured with high torque and the input diameter D4 can be up to φ255mm, which can greatly meet the customer needs. Single-stage planetary gearboxes and two-stage gearboxes are available:

.One-stage ratio : 3, 4, 5, 6, 7, 8, 9, 10

.Two-stage ratio: 12, 15, 20, 25, 30, 35, 40, 50, 60, 70, 80, 90, 100

.Note: Three-stage technical data are not available in 3F catalogue. If needed, please contact our salesmen.

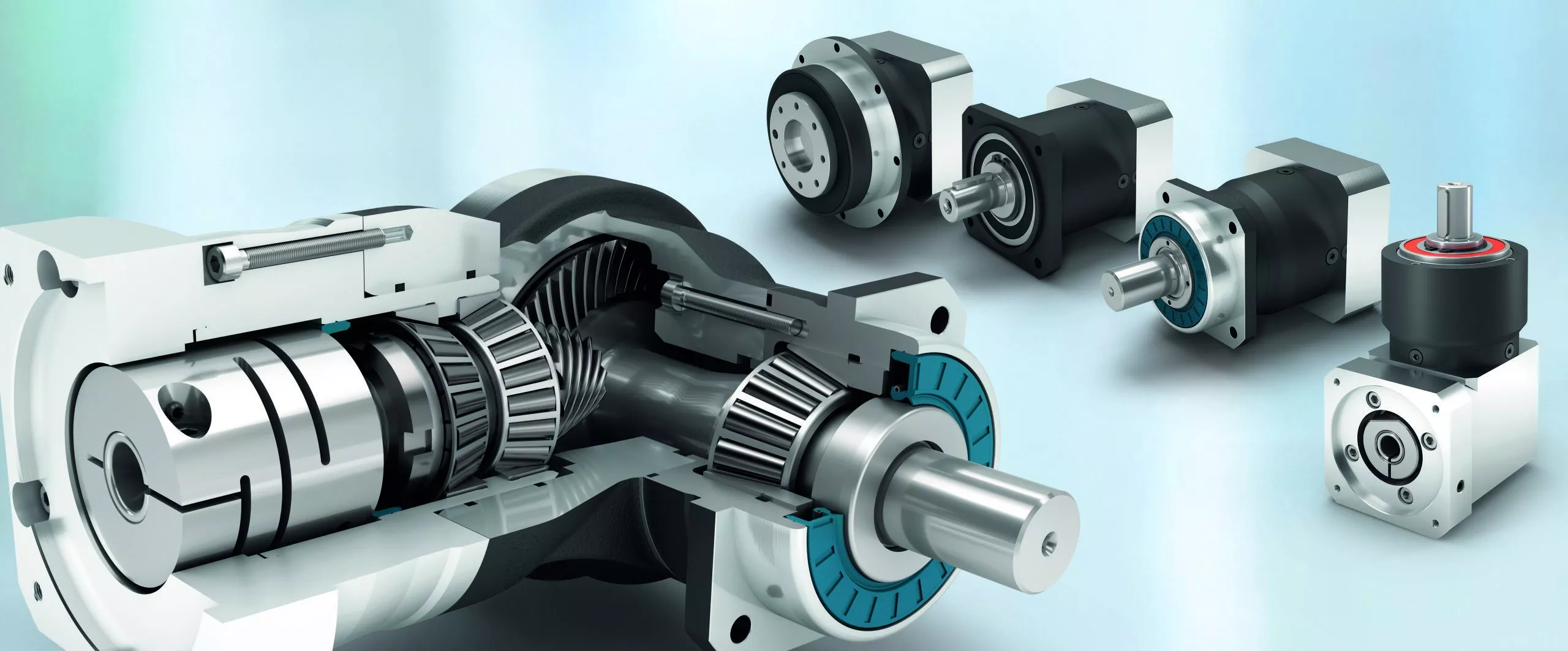

Overview of PAB Planetary Reducer

* The minimum backlash can reach to 0-3 arcmin.

* With the advantages of high High torque and high strength.

* It can be applied for any servo motors and stepper motor.

* The positioning time of starting and stoppingis shorter.

* High rigidity and high motor rotor inertia.

* Due to the miniaturization of motor power, it can achieve the stability of inertia load and small vibration.

Product Parameters

| Product type | PLS60 | PLS90 | PLS115 | PLS142 | Reduction rqatio | Number of stage | |

|

Rated output torque |

N.M | 30 | 75 | 150 | 400 | 3 | 1 |

| 40 | 100 | 200 | 560 | 4 | |||

| 50 | 110 | 210 | 700 | 5 | |||

| 37 | 62 | 148 | 450 | 8 | |||

| 27 | 45 | 125 | 305 | 10 | |||

| 77 | 120 | 260 | 910 | 12 | 2 | ||

| 68 | 110 | 210 | 780 | 15 | |||

| 77 | 120 | 260 | 910 | 16 | |||

| 77 | 110 | 260 | 910 | 20 | |||

| 68 | 110 | 210 | 780 | 25 | |||

| 77 | 120 | 260 | 910 | 32 | |||

| 68 | 110 | 210 | 780 | 40 | |||

| 37 | 62 | 148 | 450 | 64 | |||

| 27 | 45 | 125 | 305 | 100 | |||

| Life | Hour | 30,000 | |||||

| Instant stop torque | N.M | Two times of rated output torque | |||||

| Product type | PLS60 | PLS90 | PLS115 | PLS142 | Number of stage | ||

| max radial torque | 3000 | 3900 | 4300 | 8200 | N | ||

| max axial torque | 6000 | 9000 | 12000 | 19000 | N | ||

| Fullload efficiency | 98 | % | 1 | ||||

| 95 | 2 | ||||||

| weight | 3.0 | 4.3 | 9.0 | 15.4 | kg | 1 | |

| 3.8 | 5.7 | 11.6 | 18.5 | 2 | |||

| operating temperature | -25ºC~+90ºC | ºC | |||||

| IP | lp65 | ||||||

| Lubirication type | Lifetime lubrication | ||||||

| Mounting type | Any | ||||||

| The max radial and axial torque work in the location of the center of output shaft when the out speed is 100RPM. | |||||||

Detailed Photos

Application

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2024-05-17

China manufacturer Desboer NF180 Series Ratio 3-10 High Precision 180mm NF Series Planetary Gearbox for Servo Motor sequential gearbox

Product Description

Product Description

The NF180 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The ND series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NF180 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

ultra-precision

Small size

Detailed Photos

Product Parameters

| Segment number | Single segment | ||||||||||||||||

| Ratio | i | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||||||||

| Rated output torque | Nm | 550 | 990 | 1140 | 1040 | 1040 | 950 | 850 | 850 | ||||||||

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||||||||||

| Rated input speed | Rpm | 3000 | |||||||||||||||

| Max input speed | Rpm | 6000 | |||||||||||||||

| Ultraprecise backlash | arcmin | ≤1 | |||||||||||||||

| Precision backlash | arcmin | ≤3 | |||||||||||||||

| Standard backlash | arcmin | ≤5 | |||||||||||||||

| Torsional rigidity | Nm/arcmin | 145 | |||||||||||||||

| Max.bending moment | Nm | 18000 | |||||||||||||||

| Max.axial force | N | 19500 | |||||||||||||||

| Service life | hr | 30000(15000 under continuous operation) | |||||||||||||||

| Efficiency | % | ≥97% | |||||||||||||||

| Weight | kg | 28 | |||||||||||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||||||||||

| Lubrication | Synthetic grease | ||||||||||||||||

| Protection class | IP64 | ||||||||||||||||

| Mounting Position | All directions | ||||||||||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤67 | |||||||||||||||

| Rotary inertia | Kg·cm² | 28.98 | 23.67 | 23.29 | 22.75 | 22.48 | 22.59 | 22.53 | 22.51 | ||||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Lubrication Practices for Maintaining Servo Gearbox Performance

Proper lubrication is essential for maintaining the performance and longevity of servo gearboxes:

1. High-Quality Lubricants: Selecting the right lubricant is crucial. High-quality lubricants with the appropriate viscosity and additives are chosen based on factors like load, speed, and operating conditions.

2. Lubricant Compatibility: Ensure that the chosen lubricant is compatible with the materials used in the gearbox construction, including seals, bearings, and gears.

3. Regular Lubrication Checks: Regularly inspect the lubricant level and condition. Monitor for signs of contamination, degradation, or overheating.

4. Proper Lubricant Amount: Avoid overfilling or underfilling the gearbox. Follow manufacturer guidelines for the correct lubricant amount to ensure optimal performance.

5. Scheduled Lubrication Intervals: Establish a maintenance schedule for lubricant replacement based on operating hours, usage intensity, and environmental conditions.

6. Lubricant Contamination Prevention: Keep the gearbox environment clean and free from contaminants like dust, dirt, and moisture to prevent lubricant contamination.

7. Lubricant Temperature: Monitor and control the operating temperature of the gearbox to prevent lubricant breakdown and ensure proper viscosity.

8. Re-Greasing: In some cases, re-greasing may be necessary due to lubricant aging or displacement. Follow manufacturer recommendations for re-greasing intervals.

9. Seal Inspection: Check the seals regularly for wear and damage. Damaged seals can lead to lubricant leakage and contamination.

10. Expert Consultation: If unsure about lubricant selection or maintenance procedures, consult with experts or follow manufacturer recommendations.

Proper lubrication practices play a critical role in minimizing friction, reducing wear, and ensuring the efficient operation of servo gearboxes in motion control systems.

Considerations for Selecting the Right Servo Gearbox for an Application

Choosing the appropriate servo gearbox for a specific application requires careful evaluation of several key factors:

1. Torque and Speed Requirements: Determine the required torque and speed characteristics of the application, ensuring that the chosen servo gearbox can provide the necessary output.

2. Gear Ratio: Calculate the ideal gear ratio based on the desired motion profile, acceleration, and deceleration requirements.

3. Mounting and Integration: Consider the available space and mechanical layout of the machinery to choose a servo gearbox with the appropriate mounting configuration.

4. Motor Compatibility: Ensure that the servo gearbox is compatible with the specific type and size of motor being used for the application.

5. Precision and Accuracy: Evaluate the level of precision required for the application’s motion control. Choose a servo gearbox that can deliver the necessary accuracy and repeatability.

6. Load Distribution: Analyze how the load will be distributed among the gears to prevent excessive wear and ensure optimal performance.

7. Backlash and Compliance: Consider the application’s tolerance for backlash and compliance. Choose a servo gearbox with low backlash if precise positioning is essential.

8. Environmental Conditions: Factor in the environmental conditions of the application, such as temperature, humidity, and exposure to contaminants. Choose a servo gearbox with suitable sealing and protection.

9. Lubrication: Determine the lubrication requirements of the gearbox and select a model that aligns with the application’s maintenance practices.

10. Overload and Shock: Consider potential overload and shock conditions the gearbox may experience. Choose a servo gearbox that can handle sudden changes in load without compromising performance.

11. Feedback Devices: If precise motion control is required, choose a servo gearbox that is compatible with the desired feedback devices, such as encoders or resolvers.

12. Efficiency: Evaluate the efficiency of the servo gearbox to ensure that it contributes to the overall energy efficiency of the system.

13. Service and Support: Select a reputable manufacturer that offers reliable technical support, documentation, and post-purchase services.

14. Budget: Balance the performance requirements of the application with the available budget to make an informed decision.

By carefully considering these factors, engineers and designers can confidently choose the right servo gearbox that meets the specific needs of their application, optimizing performance and productivity.

Industries Utilizing Servo Gearboxes

Servo gearboxes find applications in various industries where precise motion control is essential:

1. Robotics and Automation: Servo gearboxes are widely used in robotics and automation systems for accurate and dynamic movement control, enhancing the performance of industrial robots, collaborative robots (cobots), and other automated machinery.

2. Aerospace and Aviation: The aerospace industry utilizes servo gearboxes in aircraft control systems, including ailerons, elevators, and rudders, to ensure precise and responsive flight control.

3. Medical Equipment: Medical devices and equipment, such as surgical robots, diagnostic instruments, and imaging systems, rely on servo gearboxes to achieve precise and controlled movements for medical procedures and patient care.

4. Manufacturing and Assembly: Servo gearboxes are essential in manufacturing and assembly lines for tasks such as pick-and-place operations, conveyor systems, packaging machinery, and precision machining.

5. Automotive Industry: Automotive manufacturing and testing processes benefit from servo gearboxes for tasks such as vehicle assembly, quality control, and testing systems.

6. Semiconductor Manufacturing: High-precision processes in semiconductor manufacturing, including wafer handling and positioning, utilize servo gearboxes to maintain accuracy in microchip fabrication.

7. Material Handling: Servo gearboxes play a role in material handling systems, such as automated guided vehicles (AGVs), palletizers, and cranes, ensuring smooth and controlled movement of goods.

8. Entertainment and Theme Parks: Roller coasters, animatronics, and other entertainment attractions utilize servo gearboxes to create dynamic and engaging experiences for visitors.

9. Textile Industry: Servo gearboxes are used in textile machinery for processes like spinning, weaving, and knitting, enabling precise control of thread tension and fabric movement.

10. Research and Development: In research settings, servo gearboxes are employed for experimentation, testing, and prototyping of mechanical systems and prototypes.

Servo gearboxes provide the necessary precision, flexibility, and reliability required in these industries, enabling advanced motion control and enhancing the efficiency and performance of various applications.

editor by CX 2024-05-14

China Best Sales Double Stage Ratio 16-100 ND 064amm Type Transmission Planetary Gearbox Helical Gearbox for Servo Motor, Desboer sequential gearbox

Product Description

Product Description

The ND064A series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The ND series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: ND064A Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

ultra-precision

Small size

Detailed Photos

Product Parameters

| Segment number | Double segment | ||||||||

| Ratio | i | 16 | 20 | 25 | 35 | 40 | 50 | 70 | 100 |

| Rated output torque | Nm | 45 | 45 | 55 | 45 | 45 | 55 | 45 | 35 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||

| Rated input speed | Rpm | 5000 | |||||||

| Max input speed | Rpm | 10000 | |||||||

| Ultraprecise backlash | arcmin | / | |||||||

| Precision backlash | arcmin | ≤5 | |||||||

| Standard backlash | arcmin | ≤7 | |||||||

| Torsional rigidity | Nm/arcmin | 13 | |||||||

| Max.bending moment | Nm | 125 | |||||||

| Max.axial force | N | 1050 | |||||||

| Service life | hr | 30000(15000 under continuous operation) | |||||||

| Efficiency | % | ≥94% | |||||||

| Weight | kg | 1.6 | |||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||

| Lubrication | Synthetic grease | ||||||||

| Protection class | IP64 | ||||||||

| Mounting Position | All directions | ||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤58 | |||||||

| Rotary inertia | Kg·cm² | 0.03 | |||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Compatibility of Servo Gearbox with a Specific Motor

The compatibility between a servo gearbox and a specific motor depends on several key factors:

1. Mounting Configuration: The mounting interface of the servo gearbox and motor must be compatible. This includes the type of coupling, flange size, and bolt pattern. Proper alignment ensures efficient power transmission and minimizes mechanical stress.

2. Shaft Diameter and Keyway: The diameter and keyway of the motor shaft must match the input shaft of the servo gearbox. A precise fit prevents slippage and ensures accurate torque transmission.

3. Torque and Speed Ratings: The torque and speed requirements of the application should align with the torque and speed ratings of both the motor and gearbox. Oversizing or undersizing either component can lead to inefficient operation and premature wear.

4. Inertia Matching: Inertia matching between the motor and gearbox helps prevent resonance and oscillations in the system. An appropriate inertia match ensures smooth and precise motion control.

5. Backlash and Stiffness: The gearbox’s backlash (play in the gears) and stiffness characteristics should match the application’s requirements. Low backlash and high stiffness are crucial for accurate positioning tasks.

6. Efficiency and Heat Dissipation: The combined efficiency of the motor and gearbox affects the overall system efficiency. Inadequate efficiency can lead to energy losses and excessive heat generation.

7. Service Life and Maintenance: Compatibility also involves considering the expected service life and maintenance requirements. A well-matched motor-gearbox combination enhances the durability and reliability of the motion control system.

8. Control and Feedback: The control system’s capabilities, such as closed-loop control and feedback devices, play a role in determining compatibility. The motor and gearbox should provide the necessary interfaces for effective integration into the control system.

Manufacturers and engineers often provide guidelines and compatibility charts to assist in selecting the right servo gearbox for a specific motor. Considering these factors ensures optimal performance, efficiency, and longevity of the motion control system.

Precision of Gear Tooth Profiles in Servo Gearboxes

Manufacturers take several measures to ensure the precision of gear tooth profiles in servo gearboxes:

1. Advanced Manufacturing Processes: Manufacturers use advanced machining techniques such as CNC (Computer Numerical Control) machining and grinding to achieve high precision in gear tooth profiles. These processes allow for accurate shaping and finishing of the gear teeth.

2. Quality Materials: High-quality materials with consistent properties are selected for manufacturing gear components. This ensures uniformity in the gear teeth and minimizes variations that could affect precision.

3. Tight Tolerances: Manufacturers set tight tolerances for gear tooth dimensions, including pitch, profile, and helix angle. This helps to maintain precise engagement between gear teeth, reducing backlash and ensuring accurate motion control.

4. Quality Control: Rigorous quality control measures are implemented at various stages of the manufacturing process. This includes inspections, measurements, and tests to verify that gear tooth profiles meet the required specifications.

5. CNC Gear Inspection: Manufacturers use CNC gear inspection machines that can measure and analyze gear tooth profiles with high accuracy. These machines generate detailed reports about tooth geometry, ensuring compliance with design specifications.

6. Computer-Aided Design (CAD) and Simulation: Manufacturers use CAD software to design gear tooth profiles with precision. Simulation tools analyze how different factors, such as material properties and manufacturing processes, affect the final gear tooth shape.

7. Profile Corrections: In some cases, manufacturers apply profile corrections to optimize gear tooth profiles. These corrections compensate for any deviations that may occur during the manufacturing process.

8. Feedback from Application: Manufacturers often collaborate closely with end-users to gather feedback on the performance of gearboxes in real-world applications. This feedback helps refine the manufacturing process and improve the precision of gear tooth profiles.

The combination of advanced manufacturing techniques, strict quality control, and continuous improvement processes ensures that servo gearboxes maintain the precision required for accurate motion control in various applications.

Contribution to High Accuracy and Repeatability

Servo gearboxes play a crucial role in achieving high accuracy and repeatability in motion control systems:

Precise Positioning: Servo gearboxes are designed to deliver precise angular displacement, allowing machines to accurately reach specific positions and orientations. This accuracy is vital in applications like robotic arms, CNC machines, and medical devices.

Low Backlash: Servo gearboxes are engineered to minimize backlash, which is the amount of play or lost motion between gear teeth. Low backlash ensures that any change in input direction is immediately translated into an accurate output movement, reducing errors and deviations.

High Torque Transmission: Servo gearboxes are capable of transmitting high torque with minimal energy loss. This enables precise control of rotational forces, ensuring that the output movement corresponds precisely to the input command.

Dynamic Response: Servo gearboxes exhibit rapid and accurate response to input signals. This responsiveness is crucial for applications requiring quick changes in motion, such as industrial robots, where rapid and precise movement is necessary for tasks like pick-and-place operations.

Feedback Systems: Servo systems often incorporate feedback devices like encoders and resolvers. These devices provide real-time information about the actual position, speed, and direction of the output shaft. The feedback data allows the servo controller to make continuous adjustments, resulting in accurate positioning and motion control.

Closed-Loop Control: Many servo systems operate in a closed-loop control configuration. In this setup, the controller continuously compares the desired position with the actual position using feedback data and makes corrections as needed. This closed-loop approach ensures that any errors or disturbances are quickly corrected, maintaining accuracy over time.

High-Resolution Encoders: Servo gearboxes often use high-resolution encoders that provide fine position feedback, enabling precise control of movements down to fractions of a degree. This level of resolution contributes to high accuracy in positioning.

Overall, servo gearboxes contribute to achieving high accuracy and repeatability by combining precision design, low backlash, responsive control, and feedback mechanisms. These characteristics make them essential components in applications where precise and repeatable motion is required.

editor by CX 2024-05-10

China high quality Desboer High Precision 42mm Nhk Series CZPT Planetary Gearbox for Servo Motor sequential gearbox

Product Description

Product Description

The NHK series is an economic version with a round body design, an integrated sun gear motor shaft design, and high-strength deep groove ball bearings. Mainly used in injection moulding robots, food packaging machines, filling machine lines, labelling machines, appliance production lines, non-metal processing equipment and many other industries.

Applicable industries:

Injection moulding robots, food packaging machines, filling machine lines, labelling machines, appliance production lines, non-metal processing equipment and many other industries.

Product Name: High Precision Planetary Gedarbox

Product Series:NHK Series

Features:High precision,low noise,light weight

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

Advantages:

High precision

Low noise

Light-weight

Detailed Photos

Product Parameters

| Frame | Model | Ratio | Nominal | Maximum | Emergency | Nominal | Maximum | Permitted | Permitted axial load | Maximum | Maximum | Weight | Moment | Moment |

| size | output torque | output torque | stop torque | input speed | input speed | radial load | radial load | axial load | of inertia(≤Φ8) | of inertia(≤Φ14) | ||||

| [Nm] | [Nm] | [Nm] | [rpm] | [rpm] | [N] | [N] | [N] | [N] | [KG] | [kgcm²] | [kgcm²] | |||

| 42 | single | 3 | 6 | 12 | 30 | 4000 | 8000 | 240 | 270 | 710 | 640 | 0.6 | 0.053 | 0.091 |

| 4 | 9 | 18 | 35 | 4000 | 8000 | 270 | 300 | 710 | 640 | 0.041 | 0.079 | |||

| 5 | 9 | 18 | 35 | 4000 | 8000 | 290 | 330 | 710 | 640 | 0.036 | 0.074 | |||

| 6 | 9 | 18 | 35 | 4000 | 8000 | 310 | 360 | 710 | 640 | 0.034 | 0.072 | |||

| 7 | 9 | 18 | 35 | 4000 | 8000 | 320 | 380 | 710 | 640 | 0.032 | 0.071 | |||

| 8 | 9 | 18 | 35 | 4000 | 8000 | 340 | 410 | 710 | 640 | 0.031 | 0.070 | |||

| 9 | 6 | 12 | 30 | 4000 | 8000 | 350 | 430 | 710 | 640 | 0.031 | 0.069 | |||

| 10 | 6 | 12 | 30 | 4000 | 8000 | 360 | 450 | 710 | 640 | 0.030 | 0.069 |

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Customization of Servo Gearboxes for Specific Industrial Needs

Servo gearboxes can indeed be customized to meet specific industrial requirements. Manufacturers offer customization options to ensure that the servo gearboxes are optimized for the intended applications:

1. Gear Ratio Selection: Depending on the desired speed and torque output, manufacturers can provide various gear ratios to achieve the required motion characteristics.

2. Torque and Speed Ratings: Servo gearboxes can be tailored to handle different torque and speed demands, ensuring that they can efficiently operate within the specified parameters of the application.

3. Mounting Configurations: Manufacturers offer various mounting options, such as flange mounts or shaft mounts, to suit the mechanical layout of the machinery.

4. Output Shaft Configuration: Custom output shaft configurations, such as different diameters or keyway options, can be provided based on the integration requirements.

5. Environmental Considerations: For applications with specific environmental conditions, such as high humidity or extreme temperatures, servo gearboxes can be designed with protective features or special coatings.

6. Lubrication and Sealing: Custom lubrication options and sealing mechanisms can be incorporated to ensure optimal performance and longevity in the given environment.

7. Feedback Devices: Some applications may require specific feedback devices, such as encoders or resolvers, for precise motion control. Manufacturers can integrate these devices into the gearbox design.

8. Noise Reduction: Customized designs can include features that reduce noise and vibration, which is crucial in noise-sensitive applications.

9. Compact Designs: Manufacturers can work on compact designs to accommodate space constraints in the machinery.

10. Integration with Motors: Customized servo gearboxes can be designed to seamlessly integrate with specific types of motors, ensuring efficient power transmission.

By offering customization options, manufacturers enable industries to obtain servo gearboxes that perfectly align with their unique industrial needs, ultimately enhancing performance, precision, and overall system efficiency.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2024-05-03

China manufacturer in Stock Brand New CZPT CZPT Hw25712 Worm Gearbox Assembly Quick Transmission sequential gearbox

Product Description

Product Description

|

item |

Sinotruk CHINAMFG Hw25712 Gearbox Quick Transmission Assembly |

|

Warranty |

12 months |

|

Place of Origin |

ZheJiang ,China |

|

Car Model |

CHINAMFG (CNHTC) |

|

Size |

Original Size |

|

Condition |

New |

|

Product name |

Gearbox |

|

Transmission Model |

6 AP 1700 B |

|

Weight |

225kg |

|

Quality |

High-Quality |

|

Packing |

Customers’ Requirement |

Detailed Photos

Company Profile

ZheJiang Yontan Import and Export Co., Ltd. was established in HangZhou, the capital of ZheJiang Province, a famous national historical and cultural city with profound heritage. The company is mainly engaged in the export of complete vehicles of SINOTRUC, HOWO, SHACMAN, FOTON, FAW, XIHU (WEST LAKE) DIS., XIHU (WEST LAKE) DIS.FENG and other brands. It is engaged in the export sales of a full range of truck accessories and assemblies. The products distributed by the company are mainly supplied to major domestic transportation units, oil and gas transportation teams, municipal engineering fleets and civil engineering fleets, as well as major foreign construction companies and transportation companies.

On the basis of the continuous development of the company’s business, we are committed to exploring the international market. So far, our market has covered China, Eastern Europe, the Middle East, Africa, Southeast Asia, South America and other countries and regions. Our integrity is everywhere and we are deeply trusted by customers. Our company has a large warehouse and a professional management team, which can quickly find suitable parts for customers, and can provide services such as good packaging, safe storage, and fast transportation to meet the diverse needs of customers at any time.

The company adheres to the concept of “integrity, CHINAMFG and sustainable”, and sincerely welcomes customers to come to our company to discuss business cooperation.

Certifications

Packaging & Shipping

Customer Visit

h

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24h Full Technical Support |

|---|---|

| Warranty: | 12 Months |

| Type: | Gearbox |

| Certification: | ISO9001 |

| Driving System Parts: | Gearbox |

| Electrical System Parts: | Gearbox |

| Customization: |

Available

| Customized Request |

|---|

Can a Worm Gearbox Be Used in Heavy-Duty Machinery?

Yes, a worm gearbox can be used in heavy-duty machinery and is often chosen for such applications due to its inherent characteristics and advantages:

- High Torque Transmission: Worm gearboxes are known for their ability to transmit high torque loads, making them suitable for heavy-duty machinery that requires significant power transmission.

- Load Distribution: The design of worm gears provides robust load distribution and excellent contact between the worm and worm wheel teeth. This enhances their load-carrying capacity, making them capable of handling heavy loads without premature wear or failure.

- Compact Design: Worm gearboxes are compact and offer high reduction ratios in a single stage. This allows for the reduction of high input speeds to lower output speeds, often required in heavy-duty machinery.

- Overload Protection: Worm gears have a natural self-locking feature, which means the gear cannot be easily back-driven by external forces. This feature provides inherent overload protection, preventing damage to the gearbox and machinery in cases of sudden load spikes.

- Smooth Operation: Worm gearboxes offer smooth and steady operation, which is crucial for heavy-duty machinery where precision and controlled movement are essential.

However, when considering the use of a worm gearbox in heavy-duty applications, it’s important to ensure proper engineering and sizing. The design should account for factors such as load, speed, duty cycle, lubrication, and temperature to ensure optimal performance and longevity.

Overall, worm gearboxes are well-suited for heavy-duty machinery across various industries, including mining, construction, manufacturing, and more.

Worm Gearbox vs. Helical Gearbox: A Comparison

Worm gearboxes and helical gearboxes are two popular types of gear systems, each with its own set of advantages and disadvantages. Let’s compare them:

| Aspect | Worm Gearbox | Helical Gearbox |

| Efficiency | Lower efficiency due to sliding friction between the worm and worm wheel. | Higher efficiency due to rolling contact between helical gear teeth. |

| Torque Transmission | Excellent torque transmission and high reduction ratios achievable in a single stage. | Good torque transmission, but may require multiple stages for high reduction ratios. |

| Noise and Vibration | Generally higher noise and vibration levels due to sliding action. | Lower noise and vibration levels due to smoother rolling contact. |

| Backlash | Higher inherent backlash due to the design. | Lower backlash due to meshing of helical teeth. |

| Efficiency at Higher Speeds | Less suitable for high-speed applications due to efficiency loss. | More suitable for high-speed applications due to higher efficiency. |

| Overload Protection | Natural self-locking feature provides some overload protection. | May not have the same level of inherent overload protection. |

| Applications | Commonly used for applications requiring high reduction ratios, such as conveyor systems and heavy-duty machinery. | Widely used in various applications including automotive transmissions, industrial machinery, and more. |

Both worm and helical gearboxes have their place in engineering, and the choice between them depends on the specific requirements of the application. Worm gearboxes are preferred for applications with high reduction ratios, while helical gearboxes are chosen for their higher efficiency and smoother operation.

What is a Worm Gearbox and How Does It Work?

A worm gearbox, also known as a worm gear reducer, is a mechanical device used to transmit rotational motion and torque between non-parallel shafts. It consists of a worm screw and a worm wheel, both of which have helical teeth. The worm screw resembles a threaded cylinder, while the worm wheel is a gear with teeth that mesh with the worm screw.

The working principle of a worm gearbox involves the interaction between the worm screw and the worm wheel. When the worm screw is rotated, its helical teeth engage with the teeth of the worm wheel. As the worm screw rotates, it translates the rotational motion into a perpendicular motion, causing the worm wheel to rotate. This perpendicular motion allows the worm gearbox to achieve a high gear reduction ratio, making it suitable for applications that require significant speed reduction.

One of the key features of a worm gearbox is its ability to provide a high gear reduction ratio in a compact design. However, due to the sliding nature of the meshing teeth, worm gearboxes may exhibit higher friction and lower efficiency compared to other types of gearboxes. Therefore, they are often used in applications where efficiency is not the primary concern but where high torque and speed reduction are essential, such as conveyor systems, elevators, automotive steering systems, and certain industrial machinery.

editor by CX 2024-04-13

China Hot selling Desboer Ndr 090 Series Right Angle High Precision High Torque Low Backlash Planetary Gearbox for Servo Motor sequential gearbox

Product Description

Product Description

The NDR090 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The ND series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NDR090 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

ultra-precision

Small size

Detailed Photos

Product Parameters

| Segment number | Single segment | ||||||||

| Ratio | i | 4 | 5 | 7 | 10 | 14 | 20 | ||

| Rated output torque | Nm | 120 | 150 | 130 | 95 | 130 | 95 | ||

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||

| Rated input speed | Rpm | 4000 | |||||||

| Max input speed | Rpm | 8000 | |||||||

| Ultraprecise backlash | arcmin | ≤2 | |||||||

| Precision backlash | arcmin | ≤4 | |||||||

| Standard backlash | arcmin | ≤6 | |||||||

| Torsional rigidity | Nm/arcmin | 31 | |||||||

| Max.bending moment | Nm | 235 | |||||||

| Max.axial force | N | 2850 | |||||||

| Service life | hr | 30000(15000 under continuous operation) | |||||||

| Efficiency | % | ≥95% | |||||||

| Weight | kg | 5.9 | |||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||

| Lubrication | Synthetic grease | ||||||||

| Protection class | IP64 | ||||||||

| Mounting Position | All directions | ||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤65 | |||||||

| Rotary inertia | Kg·cm² | 2.25 | 1.87 | ||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

The Role of Harmonic Drive Servo Gearboxes in Advanced Motion Control Systems

Harmonic Drive servo gearboxes play a crucial role in advanced motion control systems by offering several unique features:

1. High Precision: Harmonic Drive gearboxes are known for their exceptional precision due to the unique gear mechanism they employ. This precision is essential for achieving accurate and repeatable motion control.

2. Zero Backlash: Harmonic Drive gearboxes are designed with zero backlash, which means there is no lost motion between input and output. This feature ensures that the commanded motion is precisely transferred without any delays or inaccuracies.

3. Compact Design: Harmonic Drive gearboxes have a compact structure, making them suitable for applications with limited space. The compact design allows for easy integration into various systems.

4. High Torque Transmission: Despite their compact size, harmonic drive gearboxes can transmit high torque efficiently. This feature is essential for applications that require both high precision and high torque.

5. Smooth Motion: The unique wave generator mechanism in harmonic drive gearboxes contributes to smooth and continuous motion, which is particularly beneficial in applications involving robotic arms, satellite positioning, and more.

6. Reduction Ratios: Harmonic Drive gearboxes offer high reduction ratios in a single-stage, allowing for precise control of output motion even when input motion is at high speeds.

7. Low Maintenance: The absence of backlash and the use of high-quality materials result in reduced wear and maintenance requirements, enhancing the longevity of the gearbox.

8. Advanced Applications: Harmonic Drive gearboxes are commonly used in robotics, aerospace, medical equipment, automation, and other industries where precision and reliability are paramount.

Overall, harmonic drive servo gearboxes are a critical component in achieving advanced motion control, enabling engineers to design and operate complex systems with unparalleled precision and accuracy.

Real-World Examples of Products Using Servo Gearboxes

Servo gearboxes find application in various industries and products, contributing to their precision, efficiency, and performance:

- Industrial Robots: Industrial robots utilize servo gearboxes to achieve precise and controlled movements, enabling tasks such as assembly, welding, and material handling.

- CNC Machines: Computer Numerical Control (CNC) machines use servo gearboxes for accurate positioning and control of cutting tools, resulting in high-quality and complex machining operations.

- Automated Packaging Machines: Servo gearboxes play a vital role in packaging machines by ensuring precise filling, sealing, and labeling of products, leading to consistent packaging quality.

- Medical Devices: Advanced medical devices like robotic surgical systems use servo gearboxes to provide surgeons with precise control and dexterity during minimally invasive procedures.

- Textile Machinery: Servo gearboxes are employed in textile machinery to control the movement of yarn, ensuring uniform and high-quality fabric production.

- Automated Material Handling Systems: Servo gearboxes enable automated conveyors, lifts, and sorting systems to handle materials efficiently and accurately in warehouses and distribution centers.

- Printers and Plotters: High-resolution printers and plotters use servo gearboxes to precisely position print heads and ensure accurate image reproduction.

- Food Processing Equipment: Servo gearboxes are integrated into food processing machines for tasks like slicing, portioning, and mixing, ensuring consistent product quality and yield.

- Pharmaceutical Manufacturing: Pharmaceutical machinery relies on servo gearboxes for precise dosage and filling operations, crucial for drug production.

- Aerospace Components: Aerospace systems, such as landing gear mechanisms and control surfaces, use servo gearboxes to achieve precise movement and ensure the safety of flight.

These examples demonstrate the widespread adoption of servo gearboxes across various industries, where precision, accuracy, and controlled motion are critical for efficient and high-performance operations.

Variations in Servo Gearbox Designs

Servo gearboxes come in various designs to meet different torque and speed requirements:

In-Line: In-line servo gearboxes have the input and output shafts aligned in a straight line. These gearboxes are compact and well-suited for applications where space is limited. They can handle a range of torque and speed requirements, making them versatile for various motion control tasks.

Right-Angle: Right-angle servo gearboxes have the input and output shafts oriented at a 90-degree angle. These gearboxes are used when the input and output directions need to change direction, such as in applications with limited space or when the motion needs to be redirected.

Planetary: Planetary servo gearboxes use a planetary gear arrangement to achieve high torque density and compactness. They are suitable for applications requiring high torque transmission with minimal backlash. Planetary gearboxes are commonly used in robotics, CNC machines, and industrial automation.

Harmonic Drive: Harmonic drive servo gearboxes utilize a flexible spline and a wave generator to achieve high gear reduction ratios while maintaining compact size. They offer exceptional accuracy and are often used in applications requiring precise positioning, such as telescope mounts and semiconductor manufacturing equipment.

Helical: Helical servo gearboxes use helical gear teeth to achieve smooth and quiet operation. They are well-suited for applications that require low noise levels and high efficiency. Helical gearboxes are used in various industries, including packaging, printing, and medical devices.

Custom Designs: Some servo gearboxes are custom-designed to meet specific requirements of unique applications. These designs may involve modifications in gear ratios, housing materials, and sealing to ensure optimal performance in specialized tasks.

The choice of servo gearbox design depends on factors such as the required torque, speed, space constraints, efficiency, and precision. Manufacturers offer a range of options to cater to the diverse needs of motion control systems in different industries.

editor by CX 2024-04-09

China supplier CZPT Machinery Udl 7.5 B3 Series Worm Gearbox sequential gearbox

Product Description

Overview

———————————————————————————————————————————————————————————————————————————————–

Quick Details

Model: UDL Brand Name: EED

Input Speed: 1400/min Output Speed: 880~1000/min

Ratio: 1.4~7 Output Torque: 1.5~118Nm

Color: Blue/Grey or on request Origin: ZHangZhoug, China (Mainland)

Warranty: 1 Year Application: Industry

———————————————————————————————————————————————————————————————————————————————–

Supply Ability

Supply Ability: 20000 Piece/Pieces per Month

———————————————————————————————————————————————————————————————————————————————–

Packaging & Delivery

Package: Polywood Case or customized.

Port: HangZhou/ZheJiang or on request

———————————————————————————————————————————————————————————————————————————————–

| TYPE | Step-less Speed Variator |

| MODEL | UDL series size:002,005,571,571,030,050,100 |

| RATIO | 1.4~7 |

| COLOR | Blue(RAL5571)/Silver grey (RAL9571) or on your request |

| MATERIAL | Housing:UDL 002,005,571 Aluminum Alloy ; UDL 571,030,050,100 Cast Iron |

| PACKING | Polywood Case or customized. |

| BEARING | C&U |

| SEAL | SKF |

| WARRANTY | 1 Year |

| INPUT POWER | 0.18kw,0.37kw,0.55kw,0.75kw,1.1kw,1.5kw,2.2kw,3.0kw,4.0kw,5.5kw,7.5kw |

| USAGES | Foodstuffs, Ceramics, Packing, Chemicals, Pharmacy, Plastics, Paper-making, Machine-tools |

| IEC FLANGE | IEC standard flange or on request |

| LUBRICANT | UB-3 |

| PAM | P | N | M | 0 | D | b | t | T | |

| IEC | |||||||||

| UDL002 | 63B5 | 140 | 95 | 115 | M8 | 11 | 4 | 12.8 | 4 |

| UDL005/TXF005 | 71B5 | 160 | 110 | 130 | M8 | 14 | 5 | 16.3 | 5 |

| UDL571/TXF571 | 80B5 | 200 | 130 | 165 | M10 | 19 | 6 | 21.8 | 6 |

| UDL571 | 90B5 | 200 | 130 | 165 | M10 | 24 | 8 | 27.3 | 6 |

| UDL030/050 | 100B5/112B5 | 250 | 180 | 215 | M12 | 28 | 8 | 31.3 | 6 |

| UDL100 | 132B5 | 300 | 230 | 265 | M12 | 38 | 10 | 41.3 | 6 |

About Xingda since 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism field and punching/stamp

ing field since 1984. Our main product, NMRV worm gear speed reducer and series helical gearbox, XDR,

XDF, XDK, XDShave reached the advanced technique index of the congeneric European and Janpanese produc

ts, We offer standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders

of non-standard products, such as gears, shafts, punching parts ect, according to customers’ Drawings or sam-

ples.

Our company has complete set of equipment including CNC, lathes, milling machines, gear hobbing machine, g-

ear grinding machine, gear honing machine, gear shaping machine, worm grinder, grinding machines, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing machines and s-

o on. We have advanced testing equipments also.

Our company has established favorable cooperation relationships with sub-suppliers involving casting, raw mat-

erial, heat treatment, surface finishing and so on.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Step: | Stepless |

| Type: | Worm Reducer |

| Customization: |

Available

| Customized Request |

|---|

What are the Noise Levels Associated with Worm Gearboxes?

The noise levels associated with worm gearboxes can vary depending on several factors, including the design, quality, operating conditions, and maintenance of the gearbox. Here are some key points to consider:

- Design and Quality: Well-designed and high-quality worm gearboxes tend to produce lower noise levels. Factors such as gear tooth profile, precision manufacturing, and proper alignment can contribute to reduced noise.

- Gear Engagement: The way the worm and worm wheel engage and mesh with each other can impact noise levels. Proper tooth contact and alignment can help minimize noise during operation.

- Lubrication: Inadequate or improper lubrication can lead to increased friction and wear, resulting in higher noise levels. Using the recommended lubricant and maintaining proper lubrication levels are important for noise reduction.

- Operating Conditions: Operating the gearbox within its specified load and speed limits can help prevent excessive noise generation. Overloading or operating at high speeds beyond the gearbox’s capabilities can lead to increased noise.

- Backlash: Excessive backlash or play between the gear teeth can lead to impact noise as the teeth engage. Proper backlash adjustment can help mitigate this issue.

- Maintenance: Regular maintenance, including gear inspection, lubrication checks, and addressing any wear or damage, can help keep noise levels in check.

It’s important to note that while worm gearboxes can produce some noise due to the nature of gear meshing, proper design, maintenance, and operation can significantly reduce noise levels. If noise is a concern for your application, consulting with gearbox manufacturers and experts can provide insights into selecting the right gearbox type and implementing measures to minimize noise.

Worm Gearbox vs. Helical Gearbox: A Comparison

Worm gearboxes and helical gearboxes are two popular types of gear systems, each with its own set of advantages and disadvantages. Let’s compare them:

| Aspect | Worm Gearbox | Helical Gearbox |

| Efficiency | Lower efficiency due to sliding friction between the worm and worm wheel. | Higher efficiency due to rolling contact between helical gear teeth. |

| Torque Transmission | Excellent torque transmission and high reduction ratios achievable in a single stage. | Good torque transmission, but may require multiple stages for high reduction ratios. |

| Noise and Vibration | Generally higher noise and vibration levels due to sliding action. | Lower noise and vibration levels due to smoother rolling contact. |

| Backlash | Higher inherent backlash due to the design. | Lower backlash due to meshing of helical teeth. |

| Efficiency at Higher Speeds | Less suitable for high-speed applications due to efficiency loss. | More suitable for high-speed applications due to higher efficiency. |

| Overload Protection | Natural self-locking feature provides some overload protection. | May not have the same level of inherent overload protection. |

| Applications | Commonly used for applications requiring high reduction ratios, such as conveyor systems and heavy-duty machinery. | Widely used in various applications including automotive transmissions, industrial machinery, and more. |

Both worm and helical gearboxes have their place in engineering, and the choice between them depends on the specific requirements of the application. Worm gearboxes are preferred for applications with high reduction ratios, while helical gearboxes are chosen for their higher efficiency and smoother operation.

How Does a Worm Gearbox Compare to Other Types of Gearboxes?

Worm gearboxes offer unique advantages and characteristics that set them apart from other types of gearboxes. Here’s a comparison between worm gearboxes and some other common types:

- Helical Gearbox: Worm gearboxes have higher torque multiplication, making them suitable for heavy-load applications, while helical gearboxes are more efficient and offer smoother operation.

- Bevel Gearbox: Worm gearboxes are compact and can transmit motion at right angles, similar to bevel gearboxes, but worm gearboxes have self-locking capabilities.

- Planetary Gearbox: Worm gearboxes provide high torque output and are cost-effective for applications with high reduction ratios, whereas planetary gearboxes offer higher efficiency and can handle higher input speeds.

- Spur Gearbox: Worm gearboxes have better shock load resistance due to their sliding motion, while spur gearboxes are more efficient and suitable for lower torque applications.

- Cycloidal Gearbox: Cycloidal gearboxes have high shock load capacity and compact design, but worm gearboxes are more cost-effective and can handle higher reduction ratios.

While worm gearboxes have advantages such as high torque output, compact design, and self-locking capability, the choice between gearbox types depends on the specific requirements of the application, including torque, efficiency, speed, and space limitations.

editor by CX 2024-04-04

China high quality Kf Series Hardened Tooth Surface Helical Bevel B5 Mounted Gearbox with Servo Motor with Flange Connection sequential gearbox

Product Description

KF Series Hardened Tooth Surface Helical Bevel B5 Mounted Gearbox with Servo Motor with Flange Connection

Product Description

K series gearbox is 1 kind of Helical Bevel type gearbox ,it is designed based on modularization , which bring many difference kinds of combinations ,mounting types ,and structure designs .The detail classification of ratio can meet various of working condition .High Transmission efficiency ,low energy consumption, superior performance . The hard tooth surface gear use the high quality alloy steel , the process of carburizing and quenching, grinding ,which give it follow characters : Stable transmission , low noise and temperature ,high loading ,long working life. Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics,which widely use for industry equipment of metallurgy ,Building Material , Chemical , Mining , Oil, Transportation , Papermaking , Sugar making , engineering Machines ,etc.

1.Technical data:

| Product Name | KF Series Hardened Tooth Surface Helical Bevel B5 Mounted Gearbox with Servo Motor with Flange Connection |

| Gear material | 20CrMnTi alloy steel |

| Color | Blue Silver Customerized |

| Case Material | Cast iron HT200 |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CHINAMFG ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Backlash | ≤20Arcmin |

2. Installation type and output mode:

bottom seated type and large and small flange type installation, CHINAMFG shaft output.

3. Input mode:

direct motor, shaft input and connecting flange input.

4. Reduction ratio:

5.36~17396

5. Average efficiency:

95%

6.Technical parameters:

Coaxial output

Power: 0.12KW~200KW

Torque: 10N · m ~ 50000N · m

Output speed: 7 ~ 415r/min

7. Model of K series reducer:

KF37, 47, 57, 67, 77, 87, 97, 107,127, 157

Detailed Photos

Certifications

Packaging & Shipping

Installation Instructions

Company Profile

< ABOUT TILI

< WORKSHOP

< QUALITY CONTROL

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems: